7 2

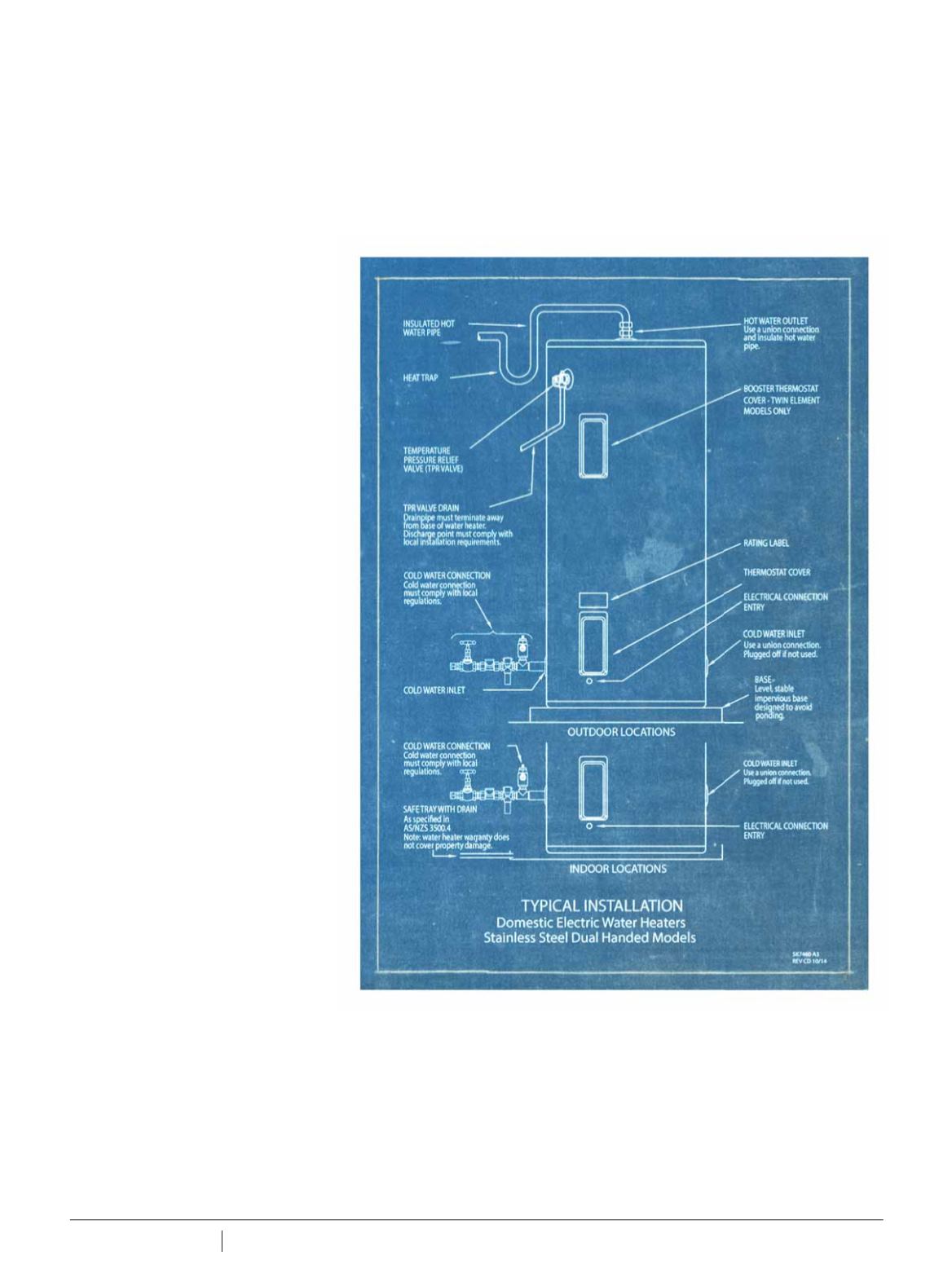

PLUMBING CONNECTION Summer 2017

CLASS IS IN - HOT WATER 101

T

his article explores the electric

water heater - its operation,

function, installation, and

commissioning, to a system that has

been an industry mainstay for many

years particularly in non-reticulated

natural gas areas.

OPERATION

MAINS PRESSURE

Electric water heaters are designed to

operate at mains pressure by connecting

directly to the mains water supply. If the

mains supply pressure in the area exceeds

the unit’s cold water supply parameters,

a pressure limiting valve must be fitted.

The supply pressure should be greater

than 350 kPa for true mains pressure

performance to be achieved.

ELEMENTS

Each electric storage water heater

is fitted with at least one tubular single

phase immersion element located

near the bottom of the tank, controlled

by a contact thermostat and over-

temperature energy cut out mechanism.

The elements are attached to the

cylinder by a mounting plate and sealed

with a rubber gasket and four screws.

The tube of the element sheath

is made from copper. A resistor is

connected between the sheath and the

mounting plate to produce a resistance

earthed element, reducing unwanted

dissipation of the protective anode.

∫

Single Element Models

This type of water heater has one

element with its own thermostat,

located at the base of the water heater.

It can be connected to an Off-Peak

(overnight) or time controlled supply,

Extended Off-Peak (overnight and day)

or Extended Time controlled supply, or a

Continuous/Domestic electricity supply.

∫

Twin Element Models

These have two separate elements,

Since the mid-1940s Australia has utilised mains pressure electric storage water heaters for use in

domestic and commercial applications,

Jon Palfrey

explains the best practices of installation and

commissioning.

IN HOT WATER -

JON PALFREY

each with its own thermostat and over-

temperature energy cut out mechanism.

One is located near the base of the

cylinder and designed to heat the whole

cylinder.

The other element is located part

way up the tank to serve as a “booster”

to heat only the upper portion of the

contents of the cylinder in conjunction

with the main element circuit.

During normal operation only the

bottom element supplies all the hot

water. During periods of high demand

the top (booster) element operates, to

provide an additional supply of heated

water.

NOTE:

Power must be available to the

top element circuit at all times for this

water heater to operate as designed.