1 2

PLUMBING CONNECTION Summer 2017

INDUSTRY NEWS

CUSTOM PLASTIC FABRICATION

Viking Plastics is an industry leader

in fabricating custom plastic tanks,

providing world class customised

products for specialised applications.

A large number of the products

are specially designed or adapted to

customers’ individual needs. With

more than 50 years of experience in

the plastic fabrication industry Viking

Plastics has the expertise to assist

with any specialised design.

“There may be occasions that non-

standard products are required. When

shape and dimensions are critical,

we will attend the site to precisely

measure the available space to ensure

the manufactured tank is tailored

to the precise specifications,” says

managing director, Malcom Ling.

In addition to prime quality PVC,

polypropylene (PP) and polyethylene

(PE) plastic, Viking Plastics utilise

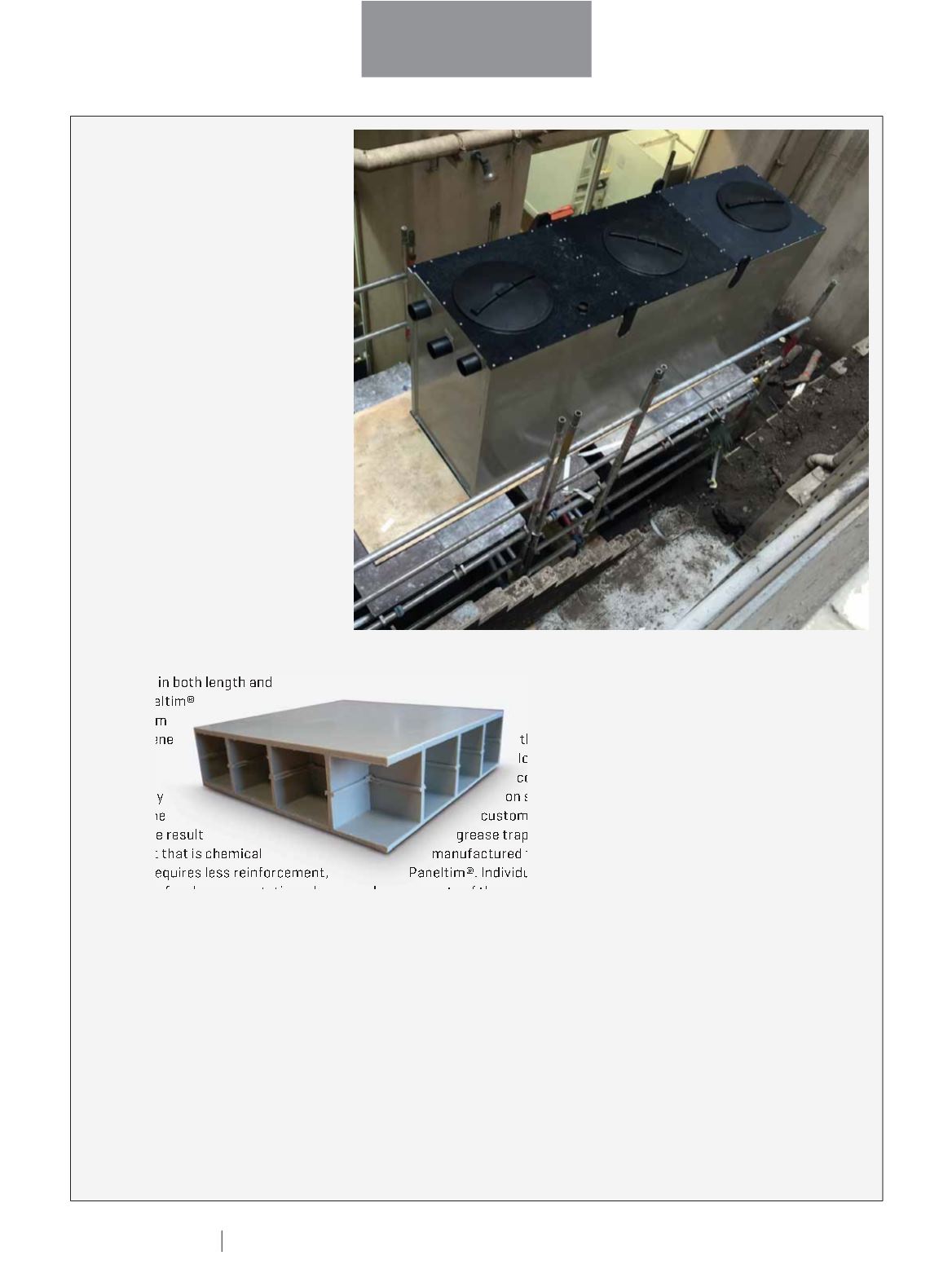

Paneltim®, an innovative 50mm

thick, dual skin sandwich panel that

is suitable for welding construction.

Featuring an internal cross-rib cell

structure, it has superior strength

and rigidity in both length and

width. Paneltim®

is made from

Polypropylene

Copolymer

(PPCO) or

High Density

Polyethylene

(HDPE). The result

is a product that is chemical

resistant, requires less reinforcement,

is shockproof and ensures static and

dynamic stability.

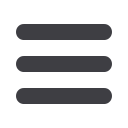

Viking Plastics recently received a

request for a 3000 litre above ground

custom sized grease trap. The trap

needed to be installed in a very difficult

location within a new restaurant in

Duckboard Place, just off Flinders Lane

in Melbourne’s CBD.

“The only available location to install

the grease trap was at ground level, at

the bottom of a seven story light shaft

in between four buildings. Access was

difficult, through a narrow passage

way, down a stair well and through a

small doorway,” says Malcom.

Due to

the difficult

location and

complexities

on site, the

custom size

grease trap was

manufactured from

Paneltim®. Individual panels

and components of the grease trap

were lowered over the side of a two

level balcony and constructed on

scaffold before finally being winched

into position.

“Every aspect of the grease trap

was customised. Most noteworthy,

all pipe-work had to be located at one

end and an internal pump out port

had to be fitted. The use of Paneltim®

construction panels, combined with

Viking’s experience in customised tank

fabrication, provided the solution for

this very challenging installation.”

Manufacturing over-sized mega

plastic tanks is all in a day’s work

at Viking Plastics. They have the

technology and expertise to fabricate

tanks to almost any specification,

including a 8,000 litre chiller tank for a

process plant in Warrnambool.

The chiller tank was built with two

chambers – one holding hot water at

50

o

C, the other chilled water. At 8m x

2m wide, the tank fitted nicely onto a

semitrailer for transport to site.

All Viking Plastics’ customised

products are fabricated in their

modern, well equipped facility located

in Melbourne, supplying Australia

wide. In addition to bespoke products,

Viking Plastics also supply a full range

of standard grease traps, trade waste

tanks, fume cupboards, chemical

resistant fume exhaust fans and,

ventilation ducting and fittings for

fume extraction.

For more information contact Viking

Plastics on

+61 3 9587 2297

or www.

vikingplastics.com.auImage above:

Duckboard Place grease trap.

Image below:

Paneltim® internal

cross-rib cell structure