Sustainable energy sources for commercial water heating

As industry and market trends change, designers and installers are now more than ever seeking ways to incorporate sustainable energy sources for services into commercial applications. Jon Palfrey tells more.

The need to provide solutions of choice to meet expectations of operating cost reduction, energy use and ultimately durability in function is here now.

This article will explore two sources of providing energy for the use of domestic heated water supply, pool/spa heating and hydronic space heating for small to large applications.

Away from traditional energy sources

With sustainable energy now high on a designer’s list of project requirements, sometimes a solar field on the roof is not feasible due to footprint limitations or solar availability.

In these circumstances, a heat pump system that doesn’t require the same footprint of solar panel fields can be an advantage where a ‘solar’ classification of energy provision is required.

Although there are some considerations for airflow and energy input, a heat pump is more flexible with the install location and can be tucked away in a basement plant room or even mounted on the roof.

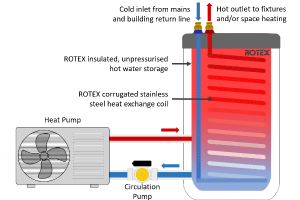

For several years the plumbing and air-conditioning industries have been seeking a heat pump solution with legitimate commercial benefits and advantages to provide higher temperatures and greater system performance characteristics. When combined with Rotex stainless steel coil tanks, renewable energy can be collected and stored in a thermal battery with minimal energy losses.

Commercial heat pumps

By definition, a commercial heat pump is a device that moves thermal energy (or heat) from one point to another. This can apply to a commercial water heating system where electrical energy is used to efficiently increase the temperature of water via a heat exchange refrigerant process.

This is essentially the same process used by conventional refrigeration and air conditioning systems but tapping into a different part of the cycle to heat water instead of cooling it. In the case with air-to-water heat pumps, heat is extracted from the surrounding environment and transferred to water to achieve temperatures up to 80° with a relatively small amount of electrical energy consumption.

Heat pumps can be used for many commercial heating or cooling applications. This can be heating or cooling water or air directly or indirectly for use in swimming pools, space heating and cooling, pre-heating or chilling for industrial processes, drying applications and more.

How it works

The thermodynamic cycle of a heat pump involves the evaporation, compression, condensation and expansion of a refrigerant. This is essentially pumping the refrigerant through a system using electricity, allowing useful heat to be input or extracted from the heat pump unit. In the case of an air-source heat pump, the outside air is used to heat the refrigerant which is then transferred to the water via an integral heat exchanger.

The efficiency of this heat pump process is referred to as Coefficient of Performance (COP) and is determined by the ratio of electrical energy input to thermal energy output. Heat pumps are regarded as a sustainable and high-efficiency heat source that can change the temperature of water via numerous energy inputs including the surrounding air, geo-thermal energy, water-to-water transfer and waste heat from industrial processes.

COP is the term to describe the ratio of useful heat output per unit of energy input. Essentially a higher COP means a more efficient heat pump, because it requires less electrical energy to generate higher thermal energy yield. For example, a COP of 3 indicates a heat pump that uses only 1kWh of electricity to transfer 3kWh of thermal energy.

Delivery performance and temperatures

Heat pumps are now available that can produce up to 80° water which can be perfectly suited to industrial wash down applications as well as food preparation and similar commercial requirements. Higher temperature generation can also reduce the size of associated energy storage, especially when using Rotex heat exchange tanks.

The commercial heat pumps used by Commercial Hot Water and Maintenance produce 64kW thermal output delivering 9,500L per hour of hot water. An advanced valve configuration allows operation in environments ranging -7 to 45° to deliver up to 80° outlet temperature. An integral pump and smart controls with RS485 connectivity allows seamless integration with building management systems and plant rooms.

Packages systems – Plug and play

Commercial Hot Water and Maintenance can provide a full plug and play packaged system completed to deliver to the project for final water and power supply connections providing significant plant installation cost reduction of labour and material use on site. Designs are modular and scalable to suit a wide range of applications.

Passive house student accomodation

Recent projects include an award-winning student accommodation building in Victoria using commercial heat pump technology in conjunction within Rotex thermal energy storage to supply 150 student apartments. Referred to as a passive house facility, services such as domestic heated water supply are provided using net zero carbon emission energy, made possible by the sustainable heat pump and thermal storage combination.

Another system delivered to site in December is designed to supply domestic hot water to over 550 students using commercial heat pumps, Rotex thermal storage, and solar electricity. This package is skid mounted and preconfigured out of the factory on Victoria’s Mornington Peninsular to be integrated with the new building’s renewable energy system using the AC•THOR 9s Photovoltaic Power Manager from my-PV.

Solar PV energy management

With more industry designers now looking for renewable energy sources, effective control over solar photovoltaic (PV) electricity generation is critical to maximise its use throughout various areas of a facility.

The AC•THOR 9s Photovoltaic Power Manager is a device that can monitor and redirect solar electricity into thermal energy storage.

When solar PV generation is in excess of the building’s electricity requirements, the excess can be diverted to heat water using resistive heating elements. When the solar yield is insufficient but there is a need for water heating, the AC•THOR 9s can direct mains power to the system. This can be configured to ensure this is done to strict thermostat and electricity tariff parameters to maximise use of renewable energy.

The AC•THOR 9s can linearly control multiple heating outputs up to 9kW. The Rotex tank is fitted with a vertically mounted 3-stage element of 3kW each (total 9kW heating capacity) to allow independent heating of the 3 layers depending on the heating requirements and availability of solar energy. Therefore, when a minimal heated draw off is required, the system operates to only meet the duty load and subsequent temperature change in the tank.

The AC•THOR 9s also has a 16A relay output to send control signals to a heat pump and configured to control other thermal loads such as space heating.

More sustainable solutions

More people are now looking for alternative energy sources to meet service requirements and there is a growing expectation from end users that associated plant and equipment is efficient, sustainable and durable as well as fit for purpose. Consider Rotex thermal storage with heat pumps or solar PV for your next water heating project