Meeting efficiency and footprint constraints with embodied energy systems

Jon Palfrey further explores how many energy sources can be captured and used for various plant and equipment services using a large residential dwelling as a project example.

As mentioned in previous articles, the world of plumbing and associated energy use for residential and commercial building services has changed both in the expectation of end users, code legislators and building designers looking to meet and provide sustainable energy needs.

Spatial allowances for plant and equipment is becoming more and more difficult to find due to the increase of medium and high-density living conditions in major capital cities as well as expanding regional centres throughout Australia.

Having the luxury of footprint to position a separate DHW plant, mechanical heating and air-conditioning system, as well as pool or spa heating equipment was once available. However, it’s now more challenging to find due to building dimensions creating a more difficult design outcome to find the space for multiple plants.

An architect and builder can now look to reduce plant footprint by bringing various energy sources to an embodied system group to serve the function and distribution of energy for services needed in a modern dwelling. The solution includes design characteristics to meet sustainable energy use and code and end user expectations of low carbon emissions and maximum energy efficiency consumption.

Now plumbers can meet these needs of footprint constraints and the energy efficiency and sustainability demands of modern living with associated energy reduction.

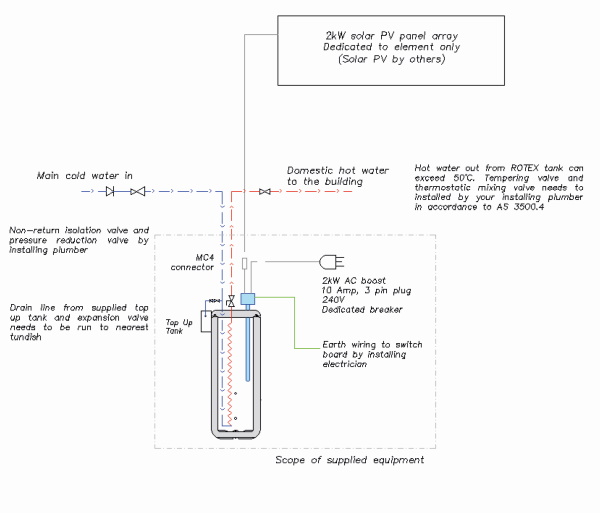

To gather energy and have it held for consumption can be achieved using a Rotex tank system which provides the integral ability to use multiple stainless-steel coils to transfer captured heat and distribute for DHW, mechanical heating and pool and spa temperature heating requirements.

A residential dwelling that consists of four bathrooms or more will typically be plumbed via a flow and return recirculation loop to provide the expectation of heated water ‘instantly’ to fixtures. This dwelling will most likely use a mechanical heating system device to provide heated water to circulate throughout floor coils or room radiator panels providing desired air conditioning temperatures.

This typical dwelling will also potentially have the need for pool and/or spa heating which can also be provided via a centralised plant that can capture energy in multiple forms, maintain required functioning temperatures and distribute to services via individual titanium coil heat exchange transfer capacities.

While the term embodied energy is generally referenced to the raw materials that go towards the manufacturing of a product or system, embodied energy can now be classified in a strict plumbing sense when considering the ability to collect energy in a centralised plant and distribute to various services requirements via a controlled system.

The potential to inject solar PV generated power supply via DC direct element cable can also provide additional energy gathering and the subsequent off grid power supply.

While solar energy transfer has been available for many years in a thermal type panel function, directly connecting via solar PV panels into a control module activating heating elements can eliminate many issues relating to thermal solar and energy transfer.

The installation of a Rotex system is no different from a conventional water heater as cold water supply with standard valve train and hot supply to fixtures with appropriate tempering or thermostatic valves for AS/NZS 3500.4 compliance.

The main difference when using a Rotex tank for energy collection and distribution is that multiple coils are available within the tank to serve as separate heat exchange mediums gathering heat via the unpressurised stored heated water.

The water in the tank once heated via gas, electricity, heat pump, solar PV or thermal collectors can accept via inlet ports at the base of the system for additional energy collection and storage.

For many years, a Rotex tank has been connected to a gas continuous flow unit to act as the primary energy source. But as expectations of energy usage change therefore as does the method of taking heat from other sources now applies.

In commercial applications, more designers are seeking to use waste heat and recover it into a heat exchange assembly and to transfer collected heat into a storage vessel. Capture it. Store it for consumption. Use it to various fixtures and services.

Architects involved in large residential dwellings can now apply greater services space flexibility, particularly if using solar PV as the constraints on flow and return piping distances don’t apply nor does the associated solar loop heat losses.

Key installation requirements

- Ensure the Rotex tank base location is firm, levelled and capable of supporting the overall tank weight once it is filled with water.

- 1 x Rotex 500 litre tank = 650kg filled weight

- 1 x Rotex 300 litre tank = 450kg filled weight

- Ensure suitable means of capturing and managing any overflow is available at the installed location as per AS 3500.4.

- Ensure the size of the door frames are large enough to allow equipment to pass through.

- Ensure reasonable access for installation, servicing and removal of all components of hot water/heating system.

- Tanks and free-standing frames must be installed on solid, level base capable of supporting the weight when filled with water and that membranes remain intact after any fasteners are installed.

- Ensure that installed equipment will not stand in water

- Whether located outdoor or indoor, the water storage tank should be installed close to the most frequently used hot water outlet/s (typically the shower in domestic applications and kitchens in commercial applications) and its position chosen with safety and service in mind.

- As close as possible to the solar panels

- Locate the Rotex tank at a minimum distance of one metre from other heat sources (>85°) (e.g. electric heater, gas heater, chimney, flue) and flammable materials.

- Locate the Rotex tank on a firm level base. Where located indoors, ensure adequate drainage is provided.

- Ensure the tank location is not exposed to frost, harsh weather condition and direct sun light and above 85˚ ambient temperature

- Appropriate enclosure needs to be installed to protect the hot water system

- The system is not suitable for installation in areas that experience sub-zero temperatures; Areas of known heavy frost or altitudes higher than 600m above sea level are not suitable for this system. (System can be installed indoors in these colder climates where the temperature is more moderate) gas booster location based on appliance type and approval

- Do not expose to ammonia, chlorine or other hazardous chemicals.

Installing a water heater can now take on more solution options and meet the ever-growing expectations of energy reduction, gathering and use.

For a hands-on experience with Rotex systems operating with various energy sources and learn about the opportunity to provide a system that can deliver ‘embodied energy’” and distribute it to single or numerous heating outlets the Thermal Energy Solutions training and manufacturing facility is now available for industry groups to visit.