A web of energy

We love product ingenuity, especially when it’s born in our own backyard and even more so when it has a role to play in the plumbing industry with a major emphasis on sustainability and energy efficient solutions. Plumbing Connection caught up with the team at Rotex to learn about its ‘web of energy’ concept.

The name Rotex may sound foreign to some; however, the first of its heating systems was installed on Aussie shores 25 years ago.

The Rotex product continues to make its mark thanks to its ability to provide safe, hygienic, energy efficient and continuous hot water using various energy input sources for large residential and commercial applications.

Plumbing Connection was invited to Energy Smart Water; the manufacturing, training, research and development facility on Victoria’s Mornington Peninsula to find out more about the thermal storage systems.

At first glance, Rotex tanks could be mistaken for fridges. Such is the simple appearance of the outer shell. Further inspection inside the tank tells a different story though and once they caught the eye of plumbing contractor Norm Anderson many years ago, they were destined to stand out as a uniquely flexible water heating system.

“Last year Norm and I conducted investigation into a suitable ‘fit for purpose’ gas system to use as a main energy source to combine with the Rotex tank system that wasn’t just a residential unit with a commercial sticker.

“We had to find a distinctive commercial system type that we could build into a plant package suitable for a range of large residential and commercial applications,” says Rotex commercial business manager Jon Palfrey.

Therefore, the Noritz gas systems were chosen with flow, performance, heavy gauge heat exchangers and durability in mind.

The Rotex thermal tanks themselves are manufactured in Germany while everything else is designed, developed and assembled here in Australia. The tanks’ thermal insulation ensures high efficiency and energy-saving heated water storage where the heated water is in a non-pressurised vessel that can accept energy yields from a number of heat sources.

The Rotex thermal storage tank systems were conceived in accordance with the latest thermal technology and water hygiene requirements. Its structure is fundamentally different from normal large volume hot water storage tanks.

“Inside the tank is a single or multiple length of stainless-steel coils. The water in the tank only comes in contact with this part of the system. The inlet and outlet connections that the installing plumber connects cold water into and takes hot water out of are only connecting to the single or multiple coils within the tank,” says Jon.

“The system’s design eliminates the enormous issue of silt coming into a water heater from the mains supply and blocking cold water inlet filter strainers, cold water component assemblies and associated system pipe manifolds which has become an increasing problem across the country. The stainless-steel coils remove the issue of bacteria, silt build up and swarf blockages.”

The minimal system footprint provides a distinct advantage for architects, plumbing designers and facility managers across the country as only a small amount of space is required in plant areas.

The ability to deliver systems on a skid package comprised of single or multiple units in a modular format is also beneficial when it comes time for delivery and installation into commercial applications.

Depending on the building and energy needs, the Rotex thermal storage systems can be adapted to many and varied water heating requirements. For large applications, such as hotels and hospitals, several thermal stores are connected in a modular fashion so that even output distribution is achieved, and output capacities can be created for virtually any size project or retrofit application.

“We have our own qualified plumbers building and assembling our plant packages,” says Rotex director Norm Anderson.

“By the time the system is delivered to site we’ve done 98% of the work. We design the systems at Thermal Energy Solutions in Sydney, build them in Melbourne and deliver across Australia.”

Music to the ears of plumbers is the fact it ‘can be designed and built as a modular “plug and play” system that can easily be plumbed to the final inlet and outlet connection points. When it comes to retrofitting, plumbers simply shut down the old system, cut into the existing pipework and connect.

According to Jon, the Rotex system, in its various capacities, can be connected in a very short period, often with no sign of heat loss throughout a building’s heated water reticulation system.

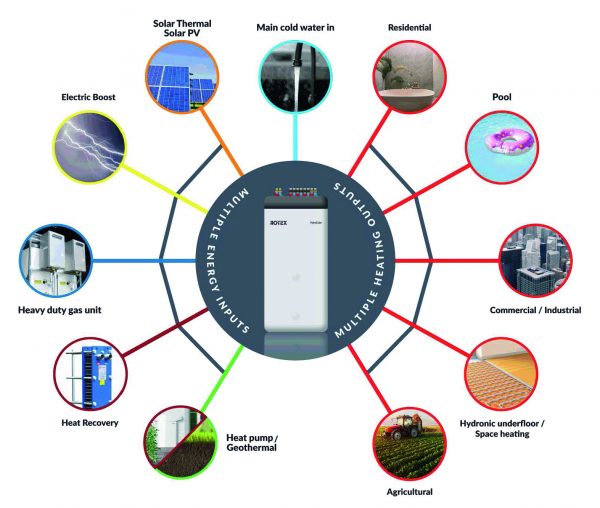

Perhaps most impressive with regards to the technology though is what the team at Rotex describe as the ‘web of energy’.

The ‘web of energy’ refers to matching water heating load demands with energy yields through heat exchange technology such as solar thermal or solar PV, electric boost, waste heat recovery, hi flow heavy duty/commercial gas units and geothermal. These provide options for energy to be gathered and delivered into the Rotex ‘thermal battery’, which allows the system to supply heat to various applications.

The Rotex system is flexible and will collect and use energy gains regardless of the required applications.

Water heating provisions include DHW, hydronic under floor or radiator heating and even pool and spa heating, all from the same or multiple yield sources. This flexibility can often half the

footprint required for multiple domestic hot water and mechanical heating systems, significantly reduce installation costs and provide greater operating cost reductions.

Not looking to compete in the everyday residential market, Rotex has largely been servicing the likes of hospitals, hotels and large domestic dwellings.

“We work with facility managers, architects and engineers that are looking for solutions for old plant equipment that has become inefficient and unreliable. We also provide systems into new build projects,” says Jon.

“A lot of clients are telling us that they’re no longer considering steam generation or even natural gas as energy sources for commercial water heating needs. With that in mind, they look to us to provide solar PV: injecting off-grid energy into a vertical heating element located in the Rotex thermal storage tanks for some commercial applications.

“One of the impressive things about this energy smart water/solar PV water heating system is the fact we could install it in the middle of Australia without mains power and create large volumes of hot water.”

For years we’ve all looked to natural gas because it’s cheap and available off the beach… but it isn’t the only considered source of energy anymore. Natural gas is not the only way of creating heat energy, and designers and facility managers are looking for alternative solutions.

“Facility managers are also keen as they look to reduce costs and overcome obstacles such as heat loss in a flow and return as part of its normal reticulation function. The energy heat loss in a building’s loop can be compensated via off grid solar PV injection which can deliver a short payback period against the initial capital to supply and fit the new Rotex system,” says Jon.

All these capabilities combined create an extremely flexible, efficient and sustainable system, all of which is further emphasised by the Energy Smart Water head office operating towards a net-zero building using Rotex thermal systems for training and demonstration purposes.

“We make all of our own power at Energy Smart Waters facility. There’s 26kW of solar on the roof, battery storage, a car charging station out the front and rainwater tanks out the back. At the end of the day we export more than we import,” says Norm.

The good news for plumbers, designers, installers and clients is it’s all available to experience firsthand at the Energy Smart Water training facility and manufacturing plant on the Mornington Peninsula.

The team has started bringing industry people through to demonstrate how the technology operates as well as explaining installation, commissioning and servicing and maintenance requirements via live working systems and real-time data.

“Our vision is for the Energy Smart Water facility in Dromana to really help take training off the page,” says Jon.