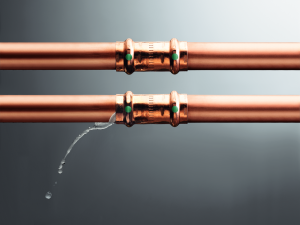

A perfect fit: press systems & crimp fittings

In the summer issue of Plumbing Connection, we highlighted the issue of crimp fittings being banned on South Australian government jobs. Now we hear from Viega, one of the world’s most recognised and respected press systems, as to why press systems have not only become popular, but also highly successful.

Viega is a family-owned company established in 1899. It has since grown to be one of the global leaders in pipe joining technology. Its press-fit systems offer ultra-fast installation – pressing takes just four seconds – which dramatically reduces labour, streamlines construction costs and, in some cases, eliminates downtime.

Given its product range and expertise in the area of press-fit, it’s of little surprise the company backs the installation type and its range unreservedly.

While smoke and fumes produced by using oxy-acetylene can harm indoor air quality, Viega technical manager Robert Hardgrove says there is also the potential for naked flames to cause surrounding materials to catch on fire. These risks become all the more problematic when buildings are older, contain flammable products or have confined spaces.

“With copper press fittings, the use of flame is eliminated altogether. This reduces the inconvenience of acquiring hot work permits and fire watches while improving safety for workers on the jobsite as well as people who use the space,” he explains.

This idea also feeds into the overall efficiency of maintenance.

“Press connections can be made on a dry or wet system, meaning there’s no need to drain or recharge. In environments like hospitals, where downtime is not an option, this benefit is crucial,” Robert says.

In soldering or brazing, it’s possible that a pipe connection can be over or under-heated. After all, it takes years to master these techniques. While overheating will also discolour pipe, both scenarios can lead to an improper seal where leaks can occur, or pressure ratings are not met.

With user-error being identified as the key reason pertaining to the decision to ban press fittings on South Australian government projects, Viega has and will continue to provide top-class training to installers, estimators, project foremen, wholesalers, engineers and educators.

“Viega offers hands-on training on-site or at Viega’s purpose-built, interactive training facility in Sydney – at no cost to the installer. Viega also has a mobile training room, the Viega Van, that conducts roadshows across the country,” Viega national sales manager Gül Parkinson says.

“Training is also encouraged by the consultants who specify the Viega Propress system into their projects. At the end of these training sessions, Viega provides a certificate confirming the installer has attended the training session,” says Gül.

Viega also follows up projects where Viega Propress is specified and installed to ensure that the installers are trained and use the right tools and fittings.

Furthermore, Viega products are only sold through wholesale distributors who understand the value of Viega products and their quality.

Viega claim the following benefits are ensured thanks to its consistently high-quality installation procedures:

- Viega Propress Smart Connect feature identifies un-pressed joints, which gives peace of mind to installers as any unpressed fittings can be detected during low pressure testing. Without this, installers could get false positives, particularly on smaller diameter pipes

- Viega Propress fittings have a cylindrical tube guide that prevents possible shearing of the sealing element when the copper tube is slid into the fitting

- Viega’s coloured dot system makes it easy to identify the sealing element in a fitting from the outside

- Viega Propress fittings have high-quality lubricated sealing elements to reduce the risk of false indication of insertion of the tube and dislodging the sealing element

- Joints have double the inherit strength of brazed joints, which means no annealing, heating or oxidising

- Reduced corrosion potential as copper is not oxidised

- 25-year warranty on Viega Propress joints whereas brazed joints do not have this period of warranty

- Viega tools have a built-in service indicator that automatically locks when service is required. The service indicator appears after 40,000 presses and locks out at 42,000. This ensures that the tool performs as it is designed to do to produce a quality press joint each time it is used