5 0

PLUMBING CONNECTION

AUTUMN 2016

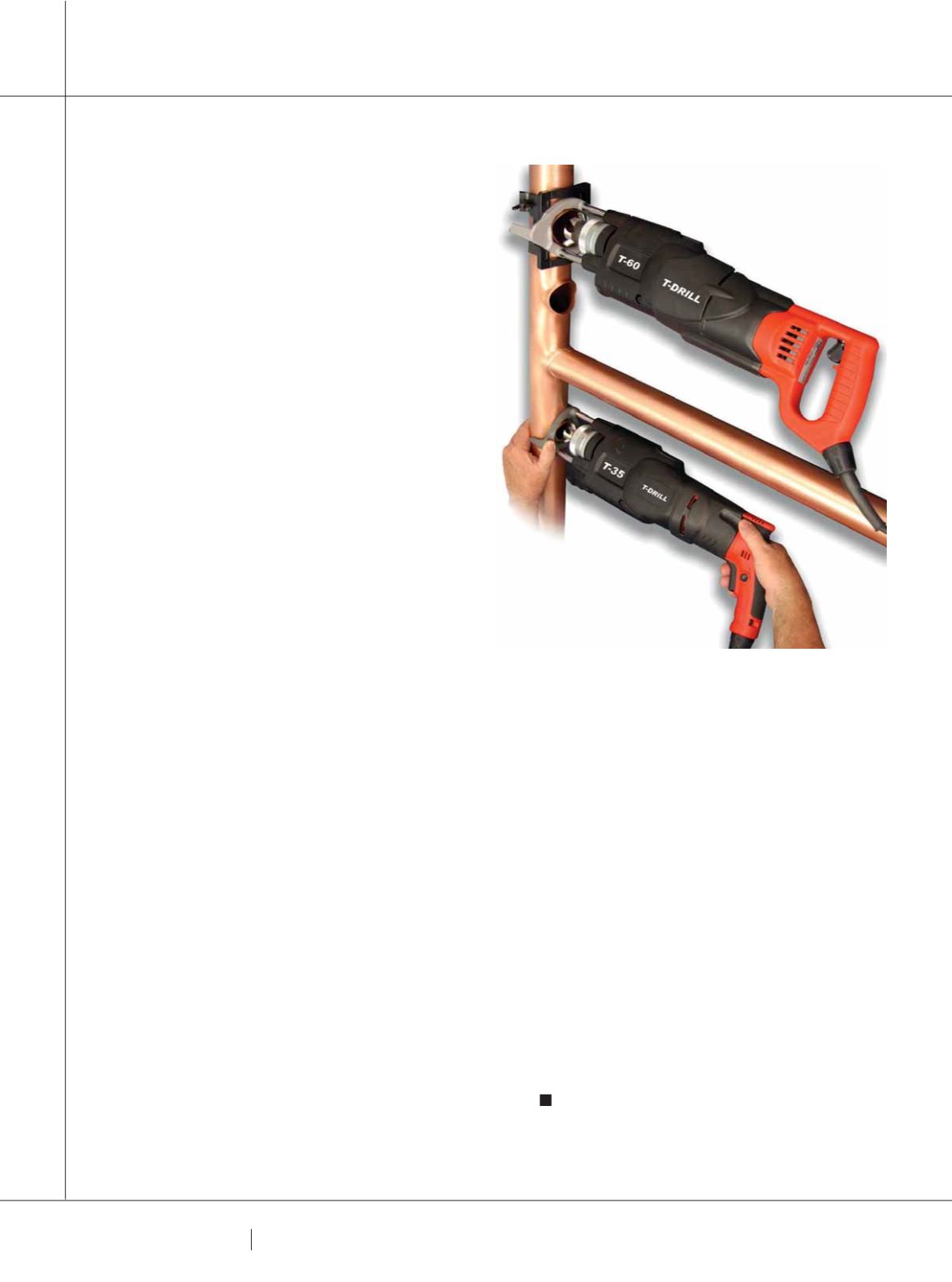

TO A TEE

E

very now and again, a great tool will come onto the

market and remain undiscovered by a large portion of

the industry for some time. T-Drill has been around,

in various incarnations, for about 30 years so it’s surprising

how many plumbers are yet to hear about it. At

Plumbing

Connection

we thought we’d remedy the situation and give

our readers a bit of a run down on what this capable machine

can do.

T-Drill is an all-in-one tool that can significantly reduce

job time for plumbers when forming tee branches in pipe

work – without the use of tee pieces. The tool works by first

drilling a pilot hole in the main tube, and then raising a collar

from the material surrounding the hole as the head retracts.

This action is made possible by two forming pins built into

the T-Drill head, these can be extended after the pilot hole

has been drilled by pulling back on the head and turning it

counter clockwise.

The branch pipe is then inserted and sealed by brazing.

Because the collar is formed so accurately, when it is brazed

the solder flows around the joint by itself under capillary

action. A branch made in this way is very strong and can

easily withstand the forces the pipe network is subjected to.

Bevis and Bartels are specialised commercial plumbers

who focus on large scale hydraulic and drainage works.

They install plumbing and drainage systems to major

construction facilities in Queensland and use T-Drill

regularly.

“We used to use a hand set of branch pullers. To make a

branch you’d have to put a drill bit onto a drill, adjust it to

whatever size branch you were drilling, and drill the hole.

Once that was done, you’d place the bobbin in the hole and

wind that out by hand with a ratchet. Then you would get

out the crimping tool and put a nipple on the pipe that you’re

feeding in so it doesn’t protrude into the pipe, then you

need to square it up and weld it. So you’d have three moving

parts, but with the T-Drill it’s all in one. You do still need the

crimping tool but T-Drill is still a lot quicker and it’s all in one

box,” foreman at Bevis and Bartels Leith Naismith says.

Because T-Drill creates consistent joins, any chance of

leakage is greatly reduced. With support legs that keep the

tool centred on the tubing, and the ability to pull a tee in a

matter of seconds, the margin for error is minimalised while

saving significant amounts of time.

A TOOL THAT CAN HELP PLUMBERS TO FORM

TEES FASTER AND EASIER, WHILE PRODUCING

CONSISTENTLY STRONG JOINS, IS ALWAYS GOING TO

BE WORTH A LOOK.

PLUMBING CONNECTION

CHECKS

OUT T-DRILL.

The unique T-Drill action is made possible due to the T-Drill

head: it both drills and forms a collar.

TOOLS

Contact: Edro

www.edro.com.au“We mark a route on the floor for the pipe work that’s

going to hang in the air. Then we place the pipe on the

measurements from elbow to elbow (or on straight runs,

mark where the tee’s going to be), lift it off the floor into a

vice. Then just grab the T-Drill and pull your branches. Once

that’s done your pipe and everything’s ready to go up into

the air in that location, with the tees in place. Each branch

you drill is exactly the same, so once the tool is set to the

thickness of the copper you can forget it, we haven’t had any

adjustment problems with it on the way through,” Leith says.

The unique T-Drill action is made possible due to the

T-Drill head: it both drills and forms a collar. The drill core is

made of hardened steel, and the forming pins are shaped so

that they do not cause any breaks or metallurgical changes

in the collar, which would reduce the strength of the joint.

The design of the T-Drill head is basically very simple. It is

robust, withstands heavy use and is easy to service.

“Time, as we know, is money nowadays – so considering

the time it saves and the ease in which it works it is a great

tool.”