2 2

PLUMBING CONNECTION

AUTUMN 2016

COVER STORY:

PRODUCT DEVELOPMENT

A MAN BEFORE HIS TIME

Every now and then, someone

comes along with brilliant ideas

that the world isn’t ready for, just

yet. Professor John Swaffield

was one such innovator. In 1983,

the UK Confederation of British

Sanitaryware Manufacturers

commissioned a project to design,

develop and site appraise a low

volume flush WC.

Some of the criteria included:

A reduced flush volume

∫

A washdown pedestal P-trap WC

pan flushed by an independent

cistern fitted with a drop valve

∫

The potential to offer a bucket/pour flush WC pan, upgradable to

cistern flush with

the omission of a flushing rim

which could not

be cleaned by pour flushing

∫

The necessity for simplicity of design and operation

With the omission of the flushing rim, Swaffield and his team at

Heriot-Watt University in Edinburgh, Scotland developed a rimless

bowl, a three point cleaning nozzle and a reduced sized exit/trap.

The rimless bowl was easier to clean and it made it easier for it to

be adapted for pour/flush usage (i.e. for use in developing countries

where there might not be a mains supply)

Ninety five of the WC’s were installed in a housing estate in

Gaberone in Botswana where buckets would be used and water

consumption was drastically reduced.

For one reason or another, the rimless technology was never

properly commercialised. How times have changed some three

decades on…

around the rim and into the sump to achieve maximum

cleansing. It was critical to create enough water flow at the

front of the rim to clear waste out of the trap and achieve

good drain line clearance.

“We knew what we had to achieve and applied that to

our rimless technology before moving into a lot of rapid

prototyping work for performance testing evaluation.

During these phases we found that to improve the flushing

performance we needed to stabilise the flow of water at

the front of the rim while ensuring the bowl was washed

effectively. This is where we came up with the flow balancer

concept.

“A predetermined volume of flushing water meets at

the front of the bowl where its flow is redistributed via a

patented balancer, where it is redirected into the sump to

remove the waste,” Steve says.

One of the tight performance requirements Caroma has

refined is just how close to the top of the pan the water flow

travels around the bowl. Caroma’s models are set to flush

at 60mm from the top of the pan, a height that ensures

successful cleansing of the bowl area, which is what rimless

is all about.

RANGE AND INSTALLATION

Caroma’s roll-out program commences in March and it is

offering this rimless Cleanflush technology in three ranges

initially.

The Caroma Care 800 models will immediately be available

to the market including concealed and wall faced solutions.

The popular Liano and Urbane collections are the first

to offer the rimless option (while still offering traditional

models).

All Caroma Cleanflush models will come with Caroma’s

Uni-Orbital® connector, and one important point for

plumbers to note is that you must use matched pan

and cistern sets to ensure flows are balanced and meet

Standard requirements.

Caroma’s strong focus on innovation and its commitment

to fine-tune design in a practical sense should stand them

well in a market that has grown from strength to strength

in Europe. If Australia’s high uptake of past European trends

are anything to go by, they will take off here too.

WE KNEWWHAT WE HAD TO ACHIEVE

AND APPLIED THAT TO OUR RIMLESS

TECHNOLOGY BEFORE MOVING INTO A

LOT OF RAPID PROTOTYPING WORK FOR

PERFORMANCE TESTING EVALUATION.

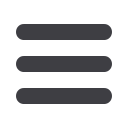

Rimless toilets have been making waves in Europe whereby

extensive testing has taken place in recent years.