18

PLUMBING CONNECTION

AUTUMN 2015

it bluntly, if you do not have the knowledge, either obtain it

via a certified course or decline the work.

“There are training programs available and there have

been national accreditation programs since 1997. The

problem is – people don’t want to send their staff to training.

Typical excuses include, ‘it costs too much, we’re busy, our

blokes are out and we can’t take them off the job’. The other

major resistance towards training is the negative attitude

directed at staff that obtain training and then leave to join

someone else or start their own business,” Bob says.

“To them I say, ‘it’s a circle. You train someone and he

leaves you; however you also employ people who have been

trained elsewhere’. It’s swings and roundabouts.

“Times have changed and the old days when plumbing

inspectors went from job to job to conduct auditing work

on behalf of various water boards has gone. They were

the fall back in a lot of instances, no doubt saving a large

number of plumbers from making costly mistakes. Now the

onus is on the plumbers themselves to ensure all work and

tests are satisfactory. The best way to do this is to keep

up with regulations and Standards, as well as continuing

professional development (CPD).”

It isn’t all bad news though. Some commonalities exist

across the board that if taken into account and rectified,

can see the tide pushing in the opposite direction when it

comes to electrofusion installations on home soil.

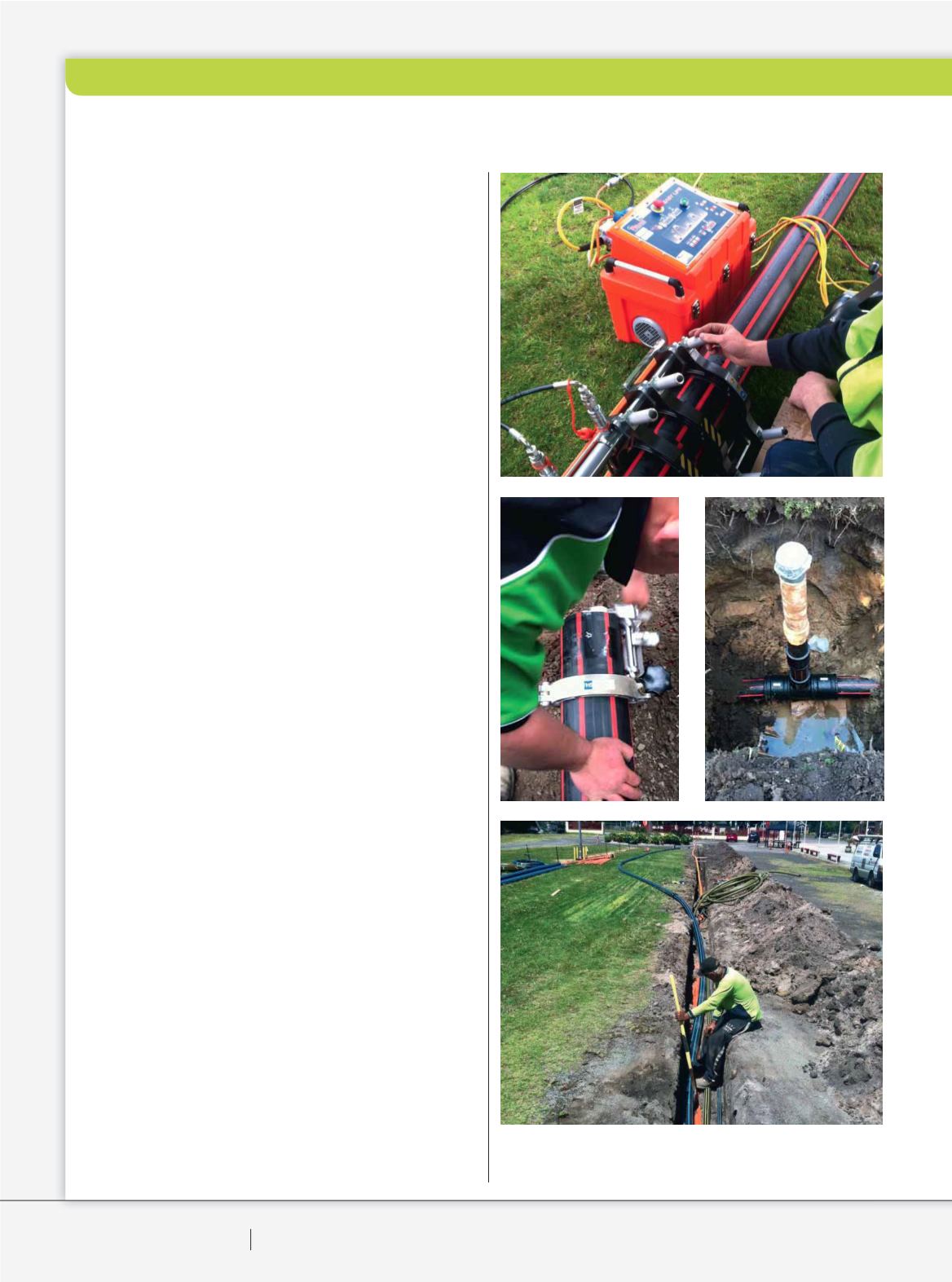

DOING IT RIGHT

Contractors who have obtained the proper training and

continually follow the manufacturer’s installation guidelines

have managed to successfully complete projects and picked

up more jobs as a result of achieving a good reputation.

One such contractor is Ecoplumb from Melbourne.

Over the years the team has successfully completed

electrofusion welded jobs for the Melbourne Zoo, Rinoldi

Pasta fire service and the Melbourne Cemetery fire mains

among plenty more of similar scale.

Managing Director Peter Monahan suggests there are a

lot of one percenters that need to be ticked off in order to

ensure a safe and sound connection is made.

PETER’S TOP TIPS:

∫ Get yourself and your team trained up in electrofusion

through an accredited training company.

∫ Always follow the procedures provided by the suppliers,

especially in regards to cool down times.

∫ Select your pipe depth into the fitting plus 50mm and then

mark it back so you know the pipe is home.

∫ Ensure you know your pipe’s outside diameter (SDR)

and the wall thickness as this will determine which

electrofusion fitting can safely be welded.

∫ Cover the end of the pipe so the ambient air doesn’t blow

through the pipe while the weld is getting done.

Get the one percenters right and you will succeed in getting

the job right. Keep a check list of things to tick off and make

sure a supervisor is on hand to evaluate the work.

COVER STORY:

ELECTROFUSION