Welding Safety: Heart of the Matter

The question has arisen whether people with cardiac pacemakers should be using electric welding equipment. The short answer is that a doctor would advise against it – and that suggests there is a real risk.

The question has arisen whether people with cardiac pacemakers should be using electric welding equipment. The short answer is that a doctor would advise against it – and that suggests there is a real risk.

However, it’s complicated, due to the wide range and severity of medical conditions as well as the diversity of welding technologies. The operation and sensitivity of the artificial timing device known as the cardiac pacemaker must be added to all the other issues you should be aware of when using electricity as a tool.

First, let’s discuss how the human body uses electricity. Every cell in the body contains the chemicals required to make a battery. Indeed, every cell passes chemicals through its delicate skin using very small electrical potentials, in the order of 0.07 of a volt (70mV).

The nervous system uses this low voltage to ‘talk’ back and forth between the nerves and the brain, then back to the muscles in the body. In comparison, the well-known AA battery gives out 1.5V.

Electricity, first noted by humans as lightning, obviously uses a much higher voltage. Lightning and human bodies, or any animal for that matter, do not get along! The electricity doesn’t even have to flow through the body to cause disruption to the nervous system.

As an electrician working around high voltages and currents in an earlier career, I can attest to the electromagnetic and electrostatic effects as well.

How electricity affects bodies

The human body can recognise as little as 1mA (1/1,000th of an Amp), and the sensation starts as a tingling that becomes more intense until it is painful at about 20mA.

More than 30mA has the potential to disrupt the normal beating of the heart, so residual current devices (RCDs) or safety switches should be installed in every workshop, not just at the switchboard. I’d recommend that people working with electrically powered machines should have RCD power points installed where they actually do their work.

Electric welders cause an RCD fault only if the primary side leaks current. Welding uses raw current, not protected current, and the welder will deliver up to its rated output current without tripping the safety switch.

If the current through the body gets much higher than 30mA, tissue can be burnt and nerves frizzled, with the result being electrical burns and loss of sensation in nerves. In the worst cases, electrical burns can mean a loss of muscle use or even of limbs.

Human skin is an insulator, although not a very good one. If the voltage is high enough, more than about 50V – or you have a cut, an open rash or burn – lower voltages can easily pass through the skin. The flesh inside the skin is essentially salty water. Wet skin conducts electricity very well, and sweat makes for a great conductor.

Almost all welders and mechanics will have experienced an electric ‘belt’ from a welder or car battery upon contacting live terminals with an exposed injury. So cover up your injuries: wear insulating gloves, and not just as heat protection.

Currents that flow through the body are called galvanic currents, named after Luigi Aloisio Galvani, an 18th century Italian physician and physicist who discovered that the leg muscles of dead frogs twitched when struck by a spark, caused by the electro-potential difference between the zinc plate on which the frogs were placed for dissection and the iron wire that Galvani slid up the spinal cord as a handle.

This was the first recorded observation of electro-potential effect of metals that would lead to the invention of the electric battery, and of bioelectricity, a field that still focuses on electrical patterns and signals in the nervous system. Unfortunately, Galvani failed to recognise either.

Galvanic currents are used in medical therapy, so they are not necessarily bad. However, high galvanic currents can change the chemical structure of your cells, causing them to die.

The human heart

The muscles in the heart operate more regularly than any other muscle in the body, both in repetition and timing. The top squeezes the blood down into the lower chambers, which then contract to squeeze the blood out of the heart, resulting in that well-known ‘ka-pump’ sound.

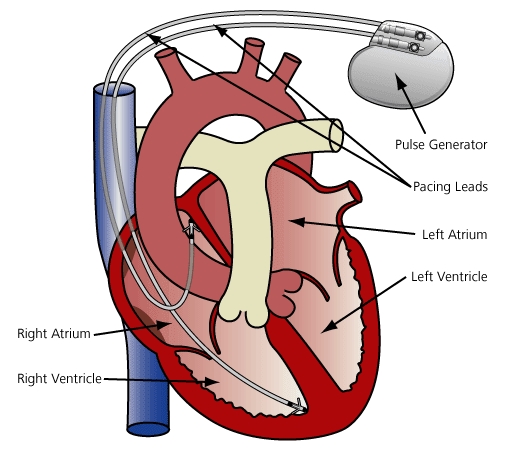

For the mechanically minded, the heart is a pair of two-stage pumps. One side takes blood from the body and pushes it towards the lungs to get rid of carbon dioxide and take in oxygen. The other side pumps the blood around the body to deliver oxygen, nutrients and chemical signals (see Figure 1).

The body employs electricity to make the heart pump, using a natural clock pulse generated in the heart but controlled by chemicals in the blood and muscles. The heart speeds up when needed, then slows down again.

In some medical conditions the heart becomes insensitive to chemical signals and doesn’t respond or slows down (bradycardia). It can also become super-sensitive and starts racing (tachycardia). Other medical conditions make heart signals ‘short-circuit’ causing the top and bottom of the pump to operate together, usually very rapidly. This is called fibrillation, or heart flutter, which is not good for the pump or its host.

When the heart’s timing signals are unreliable, an external timer is often used. The cardiac pacemaker may be ‘installed’ surgically to generate, regulate or initiate the timing signals.

The pacemaker body encloses the sensitive controls and battery, and two wires convey signals into the heart – one to the bottom chambers and one to the top chambers. The EMI problem Electro-magnetic interference (EMI) occurs when electrical fields and currents created by one system interfere with the operation of another system.

In our area of interest, the EMI comes not only from welders but also plasma cutters, sparking electric motors, radio transmitting devices and many other devices we are around on a daily basis.

All electrical appliances and tools must conform to EMI requirements set by the Australian Communications and Media Authority and referred to in the Australian and New Zealand Standards.

Of course old welders (meaning both the machines and the operators) do not always comply with the standards.

EMI and pacemakers

The pacemaker must, by its very nature, be sensitive to signals from the heart and be frugal on power for long-term reliability, working on very small voltages and currents.

Pacemaker manufacturers are aware of EMI and do their best to keep their devices immune to it. But just as rustproofing doesn’t always work the way you planned, neither does EMI immunity.

However, wires connecting the pacemaker to heart muscles act as antennas and as voltage probes. They pick up radio and electrical fields and stray voltages, which are normally filtered out by the pacemaker. When the signals are too great to ignore, they can affect the reliability of the pacemaker and therefore the signals coming from it.

What happens to the user

How a misbehaving pacemaker affects someone’s wellbeing very much depends on the job it was doing.

Some only step in if the heart is beating too slow or fast, or is getting out of rhythm. Others generate the life-giving clock signal that normally comes from the heart.

In some cases, if the pacemaker gets a wrong signal it does nothing, or at least nothing dangerous. In other cases it may kick in and set the heart rhythm to what it ‘thinks’ you should be doing – which is OK if it is thinking correctly.

In other cases it could stop, maybe to reboot, and the user may have dizziness and symptoms similar to the condition that warranted the pacemaker in the first place. In the most catastrophic circumstances, the pacemaker could fail. Depending on how much the user relies on it to survive, this could be deadly.

Precautions

Life is a risky business, but we all take risks appropriate to our level of comfort. As we get older, we become wiser – or at least more concerned about what we have left.

Most of us would know someone who can weld and would be happy to do a few welding tasks for us. So we must weigh up our advice and situations, those who rely on us and those we rely on. Call in some favours, watch from a distance, advise or confer and live to be a nuisance much longer.

If you must take the risk, which is a risk to healthy people as well, remember the workplace health and safety methods:

• Plan the work.

• Work the plan.

• Identify risks and remove them, resolve them, or guard against them to the safest practical level.

• Never work alone, especially if you have a health issue.

• Ensure your assistant is well aware of the risks and the steps to take if there is an emergency.

Finally, if you’re an extreme risk-taker, make sure your will is in order.

Special thanks to Bob’s son, Robert, a RAN medic and theatre technician, for scrutinising and correcting the medical information in this article.