Tips for Inert Gas Weld Purging of Pipes

By Dr. Michael Fletcher – Delta Consultants

Effective weld purging is only achieved by making sure that oxygen is displaced from the purge zone prior to and during welding. Any residual oxygen can cause significant loss of corrosion resistance and a reduction in joint strength. It is therefore essential to seal the pipe either side of the joint and maintain this seal throughout the process. The residual level of oxygen in the purge zone needs to be consistent with the welding procedure so continuously monitoring to ensure compliance is crucial.

1. Choose a dependable sealing material

The cheapest is seldom the best so examine the options available. Don’t be tempted to use sealing discs made from polystyrene foam, wood and cardboard – at best they leak or emit contaminants and at worst they catch fire during the hot weld cycle.

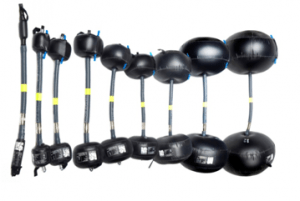

Fig 1. These examples from the QuickPurge1 range are representative of proven purge systems. They employ components made from materials that are stable, thermally resistant, durable and non-toxic. They cover the entire pipe size range between 150mm and 2400mm diameter giving an effective seal in each case and a low purge volume.

2. Use a complete purging system

Don’t try to economise by making use of whatever happens to be around at the time. Separate seals for the pipe and rubber tubing for the inert gas, all held together with bits of tape seldom succeeds. Invariably this is time consuming and can only be used once.

Find systems using inflatable dams. Commercial equipment is now available in which gas flow and pressure and purge gas quality are all pre-set. Complete monitoring instrumentation can be incorporated to ensure a high level of quality control. These systems have been designed for multiple uses and are rugged enough to cope with site conditions whilst still reducing overall purging and welding time very significantly.

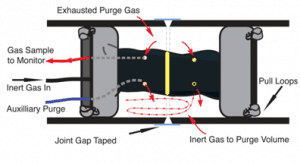

Fig 2. These PurgElite1 systems employ the latest advances in technology and are fully integrated to keep purge times and cost to a minimum. Sizes between 25 and 600 mm diameter are available. The hoses are completely flexible and allow the systems to transverse 90º bends.

3. Establish what level of oxygen in the purge gas is acceptable

There is plenty of published information available that establishes what the maximum oxygen content needs to be to prevent loss of mechanical and physical properties in the weld. This depends on the material being welded but generally, some stainless steel welding requires a low level whereas most carbon steels are much less sensitive.

4. Take care with gas flow

Whatever system is selected ensure that the inert gas enters gas slowly. Argon is heavier than air so introduce it slowly at the bottom of the weld purge space and discharge from the highest point. Helium is lighter than air and needs to be inserted at the top of a cavity and removed at the base.

Fig 3. Inflated system in place showing gas flow.

5. Don’t rush into the welding sequence

Wait until all the air has been displaced before welding. For many metals this means ensuring a residual oxygen level below 100ppm.

Traditionally, and a practice still followed even by major fabricators, this is based on pure guesswork. If the oxygen content is too high, or varies during welding, oxidation occurs and this often means rejection with the expense of re-machining and therefore production delays. It can also lead to loss of corrosion resistance in stainless steels.

6. Use a purge gas oxygen monitor

Don’t assume that allowing ‘plenty of time’ for purging will remove all the oxygen. If there are leaks in the system, turbulence or simply poor quality purge gas then oxygen levels could be way above those necessary to prevent contamination. The best solution is to use a device capable of accurate and reliable measurement of oxygen level.

Fig 4. Purge gas oxygen monitor. These instruments have been specially designed for rugged use during site welding and can measure oxygen content as low as 10ppm. They may be hand held, desk mounted or boxed for “ON SITE” use.

7. Read published information about purging

There is plenty of it and examples are shown below. Learn from the experience of others rather than using trial and error methods that could cost time and necessitate re-welding.

References

- Argweld products from www.huntingdonfusion.com

- Developments in weld purge gas oxygen monitoring technology. Stainless Steel World. March 2015.

- Guide to weld discoloration levels in stainless steel. American Welding Society. AWS D18.2:1999

- Choosing an effective weld purging technique. Stainless Steel World. May 2013

- Danger of Corrosion when Welding Stainless Steel. Food Safety Magazine Digest Nov 2014 www.foodsafetymagazine.com

- Major Advances in Weld Purge Technology. World Pipelines 2014

- Latest developments in weld purging www.energyglobal.com