How correct installation prevents common hot water system failures

Large heated water systems need professional design, installation and maintenance to avoid costly problems. John Fennell writes.The design, installation and commissioning of larger circulating heated water systems plays a significant role in the life and efficiency of the system. They can, in some cases, cause major problems for the owners and residents.

These problems may include high energy consumption, wasted water, low temperature or premature failure of system components.

The purpose of a heated water circulating system in a building is to allow a centralised heating plant to efficiently deliver hot water in a timely manner over large distances without wasting large quantities of water.

Larger circulating heated water systems must include balancing valves on the different circuits so that the heated water is distributed evenly. Without these balancing valves, water will take the shortest/easiest path to circulate and leave the more remote sections with very long waiting times to draw through hot water.

Manual balancing valves are very common, but these must be set up correctly and this can be time consuming and difficult on large installation where there are many valves. The use of thermostatic balancing valves (automatic balancing valves) is another option as they require less manual adjustment and are a dynamic self-regulating system.

Even with thermostatic balancing valves the design of the system is critical to ensure the correct pipe sizing so they don’t operate against one another. The thermostatic balancing valves should not be considered an install and forget system.

Both manual and thermostatic balancing valves need to be commissioned and the flow and temperatures verified, so the system operates as intended. They also need to be compliant with the Australian Standards, and are in line with the manufactures’ installation requirements.

With any circulating heated water system there is always air that has been dissolved in the incoming water entering the system. This air, initially dissolved in the water, will come out of the solution over time and accumulate at the highest point during periods of low flow or become entrained in the water during periods of high flow. This can result in reduced flow in some loops, air locks stopping flow completely or cavitation at pumps and areas of high turbulence.

Air elimination devices are critical in all large circulating heated water systems to allow any air in the system to be removed. These must be located at the highest point in the system and depending on the design, several air elimination devices may be required to cover all points in the piping system where air can accumulate.

Below is a general schematic, supplied by Watermark Services Group, illustrating a medium-size circulating heated water system showing the location of the balancing valves and air elimination device.

One of the most common outcomes of incorrectly set balancing valves or air trapped in the system is that someone adjusts the heated water circulating pumps to the highest setting. They do this in order to get the heated water through the system quicker without knowing the true reason the system is not operating correctly. This may cause the failure of the return pipework due to the water travelling too fast and initiating erosion corrosion.

The water velocity in the return line must be less than 1m/sec. This requires the correct sizing of the return pipe work and the correctly sized and adjusted circulating pump. The return pipe work is always smaller in diameter than the main feed pipe work as it is only returning a small proportion of the water in order to keep the heated water system hot during period of low usage.

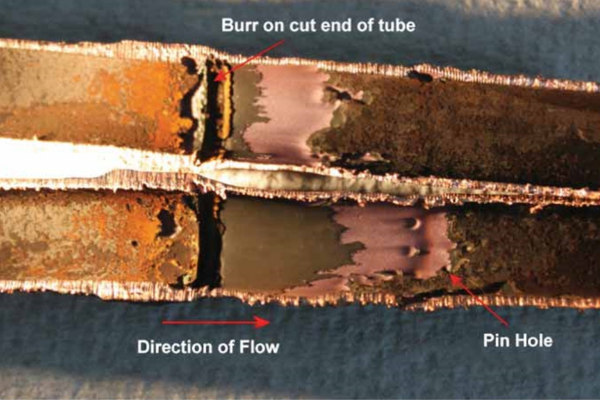

Erosion corrosion can occur under adverse conditions and is associated with cavitation. The phenomenon of erosion corrosion and cavitation can occur in systems when the flow velocity is high and either the direction of flow is sharply changed or is obstructed by something such as a burr on a cut end.

Just after a burr the pressure drops substantially which permits bubbles to form that in turn collapse when they flow into a normal pressure area. They collapse with enough force to erode microscopic pieces of metal if they are close to the tube wall. An example of such cavitation is shown below.

At an elbow, the centrifugal force flowing around a short radius bend at high velocity causes an increase in pressure at the outer portion of the bend and a resultant lowering of the pressure at the inside of the elbow. In the low pressure area, air bubbles form but these collapse just after the elbow impingement on the surface and eroding the surface.

This action may continue until perforation occurs through the wall of the tube or fitting, and the presence of dissolved gases or suspended particles exacerbates this problem.

Cavitation will affect all pipe materials and induce local increased stresses in the material. The higher the water temperature the greater the likelihood of cavitation occurring.

Below is an example of this type of failure.

With any circulating heated water systems the design and commissioning is critical, but so is the operation and maintenance during the life of the system. The ongoing maintenance needs to fix any problems that occur and not just make temporary adjustments to things like increasing pump speeds as this will ultimately cause problems in other areas and potentially reduce the life of the equipment, significantly.

Any modifications undertaken to the system should not be carried out without considering the effect the work will have on the system and performance. To ensure the longevity of any large circulating heated water systems they need to be designed by an experienced professional. In addition, competent experts are needed to correctly adjust the balancing valves and pump settings during commissioning.