The Rise of CO2 Heat Pumps

Heat pumps are now one of the main topics of discussion within the building and plumbing industry. With natural gas being phased out, developers have turned their sights onto the next method of heating hot water – and this is heat pumps. Expert Konrad Perry comments.

The technology behind heat pumps is not anything new. It is the same technology as what you may find in an air conditioning system or refrigerator. The basic principle of a heat pump is that it extracts energy from one source (such as the surrounding air). Then, with an internal compressor, it is able to multiply the electrical energy input and transfer this energy to water through an internal heat exchanger. As a result, it is not unusual to see heat pumps with a heat output that is 3–4 times greater than the electrical input required (typically this is called the coefficient of performance, or COP). For reference, condensing gas boilers and electric storage tanks have a COP less than 1.

With heat pumps being relatively new for heating domestic water in the Australian plumbing industry, this article will aim to highlight and discuss one heat pump type which is considered to be the future of hot water heating, namely CO2 heat pumps.

CO2 HEAT PUMPS

CO2 heat pumps were introduced in the early 1990s in Japan, and have now been commercialised by mainly Japanese manufacturers. In Australia, brands seen in large residential, commercial and industrial applications include the likes of Mayekawa (Hunt Heating), Mitsubishi Heavy Industries (MHIAA) and Revere (Automatic Heating), which all have the Japanese quality and reliability that consumers around the world have come to know and trust. Mayekawa and MHIAA both have WaterMark-certified heat pumps which can be directly connected to potable water, whereas the Revere typically uses a coiled tank solution to heat water.

But what is a CO2 heat pump, and is CO2 not bad for the environment?

Carbon dioxide (also known as R744) is used as the refrigerant for the heat pump and has been identified to have many benefits. It is a natural refrigerant with an ozone depletion potential (ODP) of 0 and a global warming potential (GWP) of 1. For comparison, R134a has an ODP of 0 and a GWP of 1,300, meaning that R134a (which is found in many heat pumps currently on the market) is 1,300 times more likely to warm the earth. Furthermore, many obsolete refrigerants are to be phased out in Australia in the next few years (including R134a), so it is important to look for a heat pump that will not be affected by this. In fact, Australia could be going in a similar direction to Europe, which is looking to limit the selection of refrigerant types to a GWP of 4 or less.

This also makes a CO2 hot water plant system a very attractive option for developers of apartment towers to pursue high environmental ratings for their buildings and increase the appeal of their development. By choosing a CO2 hot water plant, certain objectives can typically be achieved such as a minimum COP of 3.5, a GWP of less than 10, and ODP of zero, to name a few.

OTHER ADVANTAGES OF CO2

Besides meeting very stringent environmental design requirements, it has some key advantages over alternative refrigerant heat pumps. CO2 heat pumps have the ability to create up to 90°C hot water from a low inlet temperature of 5°C in a single pass. Where other heat pump types typically heat up water gradually, CO2 heat pumps can output water at the desired outlet temperature in an instant, which means they can maintain the required temperature at the top of the storage tank. This is likely the reason why it has seen such a large uptake by supermarkets, factories and hospitals, all of which require large quantities of hot water up to 90°C for various purposes.

I had the opportunity to see a Mayekawa ECO-CUTE CO2 industrial-grade heat pump in operation within a food factory, and observed it heating 15°C inlet water temperature to a 65°C outlet temperature. The single unit was creating around 35,000L of 65°C each day for washdown purposes with no downtime using just 25mm copper pipework and fittings. In order to do this, a CO2 system operates at a lower flow rate and therefore only requires smaller components such as pipework, pumps, valves and fittings to and from the heat pump, which can save significant costs on installation and materials.

Furthermore, this has the added benefit of being a system that does not require heating elements to properly function (something that many R134a heat pump systems require), as it can output the required temperature instantaneously. By not requiring additional ‘booster tanks’, CO2 hot water plants typically require less space than other heat pump systems, which can give valuable real estate back to the developer. Add to this the high COP of CO2 heat pumps and there can be significant electrical cost savings to the end user.

COLDER CLIMATES TOO

CO2 heat pumps also make an excellent choice in the colder parts of Australia where the winter months can reach freezing temperatures. This is because the heating ability at low ambient temperatures is superior to other alternative refrigerant types. In fact, the Mitsubishi Q-ton 30kW CO2 heat pump from MHIAA has 100% heating capacity down to -7°C.

There are a couple key considerations, however, to keep in mind if selecting a CO2 heat pump. Firstly, the price is significantly more than alternative heat pump types. Because the heat pump operates at higher internal pressures and temperatures than other refrigerant-type heat pumps, it requires stronger internal components, which add to the cost of the system. Despite this, CO2 heat pump systems typically have a faster payoff period due to their higher efficiencies when compared with alternative heat pump systems. These strong internal components also add to the durability of the heat pump.

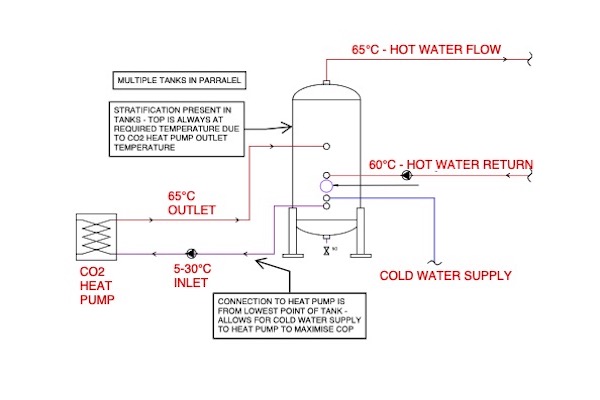

Schematic 1: CO2 heat pump plant with parallel tank arrangement.

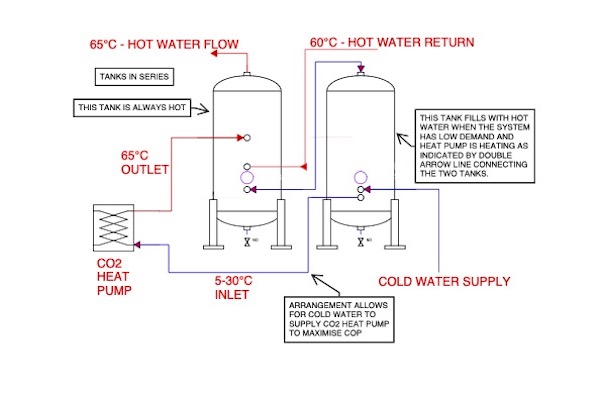

Secondly, a CO2 heat pump system design must be carefully considered, as CO2 heat pumps operate extremely efficiently with an inlet temperature below 30°C due to the way CO2 operates as a refrigerant. When the temperature exceeds 30°C, however, the pressure in the refrigerant loop can increase and the heat pump may reduce output to protect itself. As a result, the COP may be reduced. CO2 heat pump suppliers and manufacturers are aware of this and can aid with any design – but typically this can be done by either connecting the tanks in parallel (See Schematic 1) or in series (See Schematic 2). Both arrangements allow for cold water to be supplied to the heat pump during operation. Because storage tanks typically have excellent stratification, the system can operate at peak efficiency.

Schematic 2: CO2 heat pump plant with series tank arrangement.

With so many heat pumps on the market now, I always suggest to people to ‘look under the hood’ to make sure they know exactly what they are getting. With a CO2 heat pump system, not only is it highly efficient and future-proof from an environmental sustainability perspective, but its unique ability to create reliable hot water in a single pass makes it a great choice for any large-scale hot water project.

Konrad Perry is a hydraulic engineer at Aurecon with extensive experience in designing and documenting hydraulic services. Visit www.aurecongroup.com