Soaring electricity costs and gas prices are urging businesses to look for more sustainable and cost-effective hot water. San Williams looks at how Mitsubishi Heavy Industries’ Q-ton addresses the issue.

With the ever-increasing cost of electricity and gas, resistive element and gas water heaters are becoming prohibitively expensive and unsustainable for many businesses that use large volumes of hot water. As well as increase to operation costs, businesses are also seeing a huge increase in maintenance costs just to keep their aging and inefficient hot water systems operational. This is where the Q-ton CO2 heat pump offers the perfect solution.

Mitsubishi Heavy Industries sales executive Jason Parsons explains how Q-ton offers a more efficient and reliable alternative, helping businesses reduce operational costs and improve sustainability.

“With an industry-leading coefficient of performance of 4.3 (intermediate season Air on at 16°C, Water on at 17°C, Water off at 65°C), the Q-ton can reliably deliver hot water using only a fraction of the energy compared to other solutions. This in turn offers huge reductions in running costs for businesses,” Jason says.

“We have seen businesses in various industries reduce their running costs by up to 30% and see a return on investment in as little as 18 months.”

Manufactured in a state-of-the-art facility in Japan, Q-ton leverages Mitsubishi Heavy Industries’ 140 years of engineering excellence, delivering high-quality, long-lasting products to the Australian and New Zealand markets.

Easy to install and integrate into existing water systems, the Q-ton can be operated as a standalone unit or combined with up to 16 units in tandem. Its modular design allows for flexible installation and scaling to meet the specific needs of different businesses, from small establishments to large industrial facilities.

With a capacity range of 3,000L to 100,000L of water per day, the Q-ton is suitable for a wide range of commercial applications such as large-scale facilities requiring significant hot water supply.

Jason says the Q-ton is ideal for facilities requiring high-temperature water capable of producing up to 90°C sanitary-grade water for processes like cleaning, sterilisation and bottling. Its flexible design also allows for temperature adjustment, making it suitable for domestic hot water needs in healthcare, gyms, hotels and aged care homes.

“Lark Distillery in Tasmania required a reliable hot water solution to deliver approximately 6,0000L of water a day to produce its award-winning whisky. The existing electric water heater was becoming expensive and unsustainable for the business, so they adopted Q-ton in their production line. Just after installation, estimates showed the distillery anticipated to save approximately 60% per year on their energy bills,” Jason explains.

“Another success story is Warrigal Aged Care in Wollongong, which replaced its outdated and inefficient natural gas system with a Q-ton heat pump. By transitioning to Q-ton the business was able to substantially reduce energy consumption and operational costs and allocate more funds to other areas of the business such as customer care, all while moving away from fossil fuels and aligning with their corporate sustainability goals.”

He adds that a key feature of the Q-ton system, which is highly relevant to the aged care industry, is its legionella sanitary cycle designed to heat water to a temperature that effectively kills legionella bacteria. This feature ensures compliance with Australian health regulations and provides peace of mind for aged care facilities. Universities, schools and apartment buildings can also rely on the Q-ton to meet their diverse hot water needs, from lab equipment to resident comfort.

Furthermore, its advanced monitoring system, accessible via an intuitive touchscreen, enables efficient operation and maintenance. It can even be integrated into building management systems for advanced energy and water usage monitoring.

As businesses strive to reduce their carbon footprint and enhance their ESG credentials, many are turning to renewable energy solutions to replace high-polluting systems.

CO2, a naturally occurring gas, has a negligible impact on the environment. It has a low global warming potential and zero ozone depletion potential, making it a far superior choice compared to synthetic refrigerants. By utilising CO2, the Q-ton heat pump significantly reduces its carbon footprint and contributes to a healthier planet.

Unlike gas boilers which rely on fossil fuels and release harmful greenhouse gases during combustion, the Q-ton produces 76% fewer carbon emissions. The heat pump also outperforms electric water heaters, extracting heat from the environment and reducing its energy consumption and associated emissions by 74% compared to electric water heaters which directly convert electricity into heat and often suffer from energy losses during the heating process.

“Using CO₂ also helps companies comply with evolving environmental regulations that often restrict synthetic refrigerants and is an attractive solution for environmentally conscious businesses who are looking to move towards net zero or carbon neutrality,” Jason says.

The design eliminates the need for electric element boosts, ensuring a consistent hot water supply even in extremely cold temperatures. This feature is particularly beneficial for applications where ambient temperatures frequently dip below 5°C.

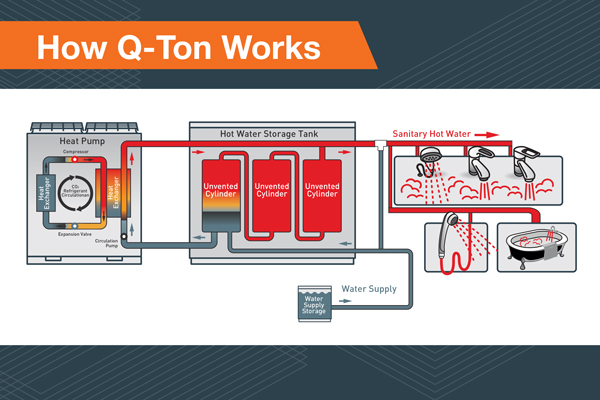

The Q-ton air-to-water heat pump operates on a highly efficient and environmentally friendly principle by absorbing heat from the surrounding air, even in cold conditions. This absorbed heat is then transferred to a CO2 refrigerant. This innovative technology extracts heat from the surrounding air and amplifies it through a two-stage compression process. The world’s first patented rotary scroll (two-stage) compressor then compresses the refrigerant, significantly increasing its temperature and pressure. This compressed, high-temperature refrigerant is used to heat water, instantly raising its temperature to between 60°C and 90°C.

The process ensures a reliable and efficient supply of hot water regardless of external weather conditions, delivering up to 90°C water even in temperatures as low as -25°C and maintaining 100% capacity down to -7°C.

To date, Q-ton has been installed at over 75 locations across both Australia and New Zealand and has helped businesses in a variety of industries drastically reduce running costs, minimise their reliance on outdated and inefficient systems and join the growing trend of reducing carbon footprint.

Learn more at Mitsubishi Heavy Industries’ website here.