Norway’s innovative wastewater treatments

Unlike many other countries, Norway is not confronted with water shortages – but it does have a strong appreciation of the need to conserve resources and protect the environment.

This has led to a focus on concepts such as ‘ecological sanitation systems’ whereby graywater is treated and reused, and blackwater from the toilet is separated at the source so that it can be transformed into valuable resources such as fertilizers, soil conditioners and bio-energy.

Prof Petter Jenssen of the Norwegian University of Life Sciences (UMB), believes that in future completely decentralized wastewater treatment systems will be common in urban areas.

“Graywater from sinks, showers and the laundry will be treated locally in compact low-maintenance systems that constitute attractive landscape elements, and these systems can coexist with decentralized water supply,” he says.

“In the Oslo suburb of Klosterenga, an experimental decentralized urban treatment system that processes graywater from 33 apartments has consistently produced swimming-water quality. An advanced nature-based treatment system is located in the courtyard of the building and consists of a septic tank from where graywater is pumped to a vertical down-flow single-pass aerobic biofilter, followed by a sub-surface horizontal-flow porous media filter.

“The effluent has consistently been better than the World Health Organization drinking water requirement of 10mg/L for nitrogen, and in relation to bacteria, faecal coliforms have been in the range of zero to 10/100ml. The small area required for the system and the high quality of effluent enables a range of urban reuse options, including discharge to wetlands or streams, irrigation and groundwater recharge, as well as domestic uses such as toilet flushing and car washing.”

UMB, in collaboration with the Ecomotive company, has developed a compact plant to treat graywater from recreational dwellings, cabins and cottages. According to Jostein Grevsgard of Ecomotive, the system is designed to treat up to 1,000L of graywater a day, and for larger requirements several units can be connected in parallel.

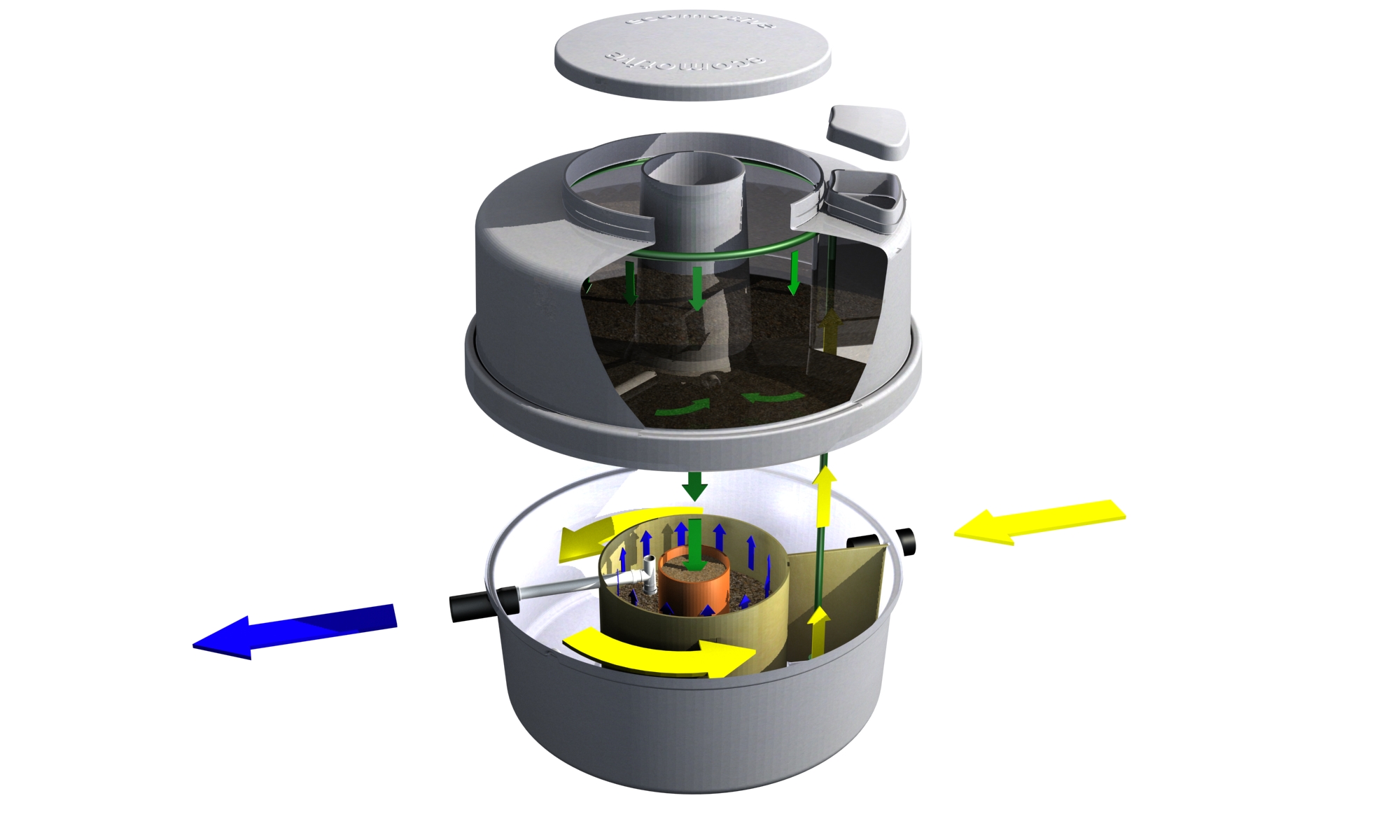

“The system consists of two sections that fit together to form a unit with a total diameter of 1.85m by 1.55m high, which includes a septic tank,” he says.

“A small pump in the septic tank distributes graywater over a biofilter in the top section so that it percolates down to the bottom section where it passes through two more filters before being used for soil irrigation or another appropriate purpose.

“All filters in the unit consist of lightweight clay aggregates and similar porous media – no chemical additions are needed in the purification process. The most distinctive aspect of the system is how compact it is, which means it is very cost effective and can be installed in a small area.

“Ecomotive has begun manufacturing the units and there are plans to market the system in a package that will include the Jets toilet system. The Ecomotive graywater system is related to the Jets toilet system in several ways. First, the Jets vacuum toilet reduces the amount of water needed for toilet flushing, as it uses less than one litre per flush. This significant reduction complements the strategy of the Ecomotive company in developing compact systems that facilitate water saving by recycling treated graywater.

“Future work will include optimization of the biofiltration part of the system, and integration of a toilet waste treatment system for the purpose of effective and hygienic resource utilization. The goal is to minimize the effect on health and the environment by increasing treatment efficiencies and reducing emissions, as well as the costs relating to water and waste treatment, and transportation. Different reuse options, for treated graywater and sludge, will be investigated as we gain experience and collect information.”

Jets toilets are available as wall or floor-mounted units in high-quality porcelain or stainless steel. The vacuum toilet system for small installations is called vacuum on demand (VOD) and is designed to accommodate up to 10 toilets. At the centre of the system is the Vacuumarator, which features an inline design with a small footprint, allowing installation flexibility and weight savings.

Jets managing director Kaare Haddal says the Vacuumarator has a motor, screw and macerator on the same shaft, and the role of the integrated macerator is to grind waste to a fine pulp for optimal transport to the sewage treatment plant.

“The system has few moving parts, and the helical screw principle uses liquid to create the seal, thus minimizing mechanical wear.

“A vacuum system can be installed using pipes as small as 32mm in diameter (1¼”), which reduces costs and space requirements. The piping system is not dependent on gravity, and a big benefit is that sewage can be ‘lifted’ to a higher level if necessary. Also, because water consumption is reduced by up to 80% compared with a conventional toilet, there is less sewage to treat, so a smaller collection tank can be used.

“Because of the flexibility of the system, Jets vacuum toilets are easy to retrofit in existing buildings, and installation costs are usually lower than for conventional toilets. Energy consumption is about 4kWh per person per year, and smaller units are available in a solar-powered version.”

The Mini Jets 10NT is the latest addition to the company’s range. Haddal says it is an exceptionally compact system for small installations, with a total weight of only 18kg (40lbs).

UMB, which has played a key role in the research and development of the Ecomotive system, is recognized as an international leader in the field of environmental technology, including developing and optimizing innovative water-saving and recycling systems for wastewater and waste.

The university’s Arve Heistad, inventor of the Ecomotive plant, says interest in graywater treatment systems is increasing in Norway.

“Based on more than 10 years of research and field experience at the university on source separating systems and constructed wetlands, we know that these systems out-compete any package treatment plant in respect to treatment efficiency on all relevant parameters.

“The only drawbacks have been the relatively high investment costs and area requirements. I wanted to create a more compact system based on the same principles, with a lower investment cost. These ideas were presented to Jets and the co-operation started.

“Since then, Ecomotive and the university have worked together on finalizing the treatment unit. The industrial experience of Jets and the close co-operation with Ecomotive have been important for the realization of the treatment unit and its competitiveness in the market.”