New valve islolates water flow

Isotec Limited has secured patents in New Zealand, Australia, Europe, the UK and USA as well as a number of other countries. The company has just received Watermark certification in Australia for the Isovalve and has signed a Distribution agreement with Abey Australia. Their product is an isolating valve which enables plumbers to connect plumbing fixtures and appliances without having to turn the water off at ‘distant’ isolating shut off valves.

“The idea for the Isovalve came about when I was at a job where all I had to do was fit a basin at a medical laboratory,” Isovalve creator Andrew Southen says.

The basin at Christchurch Radiation Laboratory was a messy job that involved turning off the entire building’s water supply.

“The test plugs had already been installed and were sticking out of the wall ready for me to remove and then connect the flexible connections from the basin faucet. It should have been easy, but being a plumber of many years I knew that turning off the water in this place was not going to be straightforward. I said to myself, I wish these test plugs were valves. If I didn’t have to turn the water off, this job would only take half an hour.”

After several calls to locate the relevant authorities and experts, Andrew found himself having to go to two remote locations to turn off both the hot and cold water. However, the first hot water tap wouldn’t turn off which resulted in Andrew having to climb a ladder into the ceiling.

With the water finally turned off and mostly drained from the pipe system, Andrew removed the test plugs.

“The bucket soon filled up and before long I had water all over the floor and still flowing. This is the time when you hope you don’t have a problem as water is an essential ingredient in the operation of this building. Finally I had the tap installed but I had to crawl back up into the ceiling, turn the hot water back on, run out to the road and turn the cold water back on, then run back to make sure I didn’t have a leak.”

All in all the job took three hours and left Andrew stressed and tired. A valve would have meant the job took 40 minutes and the client wouldn’t have had to face the ordeal of having their water turned off.

So Andrew set out to design a valve that requires no off-site mains water shut-off and saves customers time, money, water and energy.

Since the idea formed in 2006, the invention first made from a crude piece of brass, has been redeveloped and continuously improved on site to the point where it can now be taken to the international market.

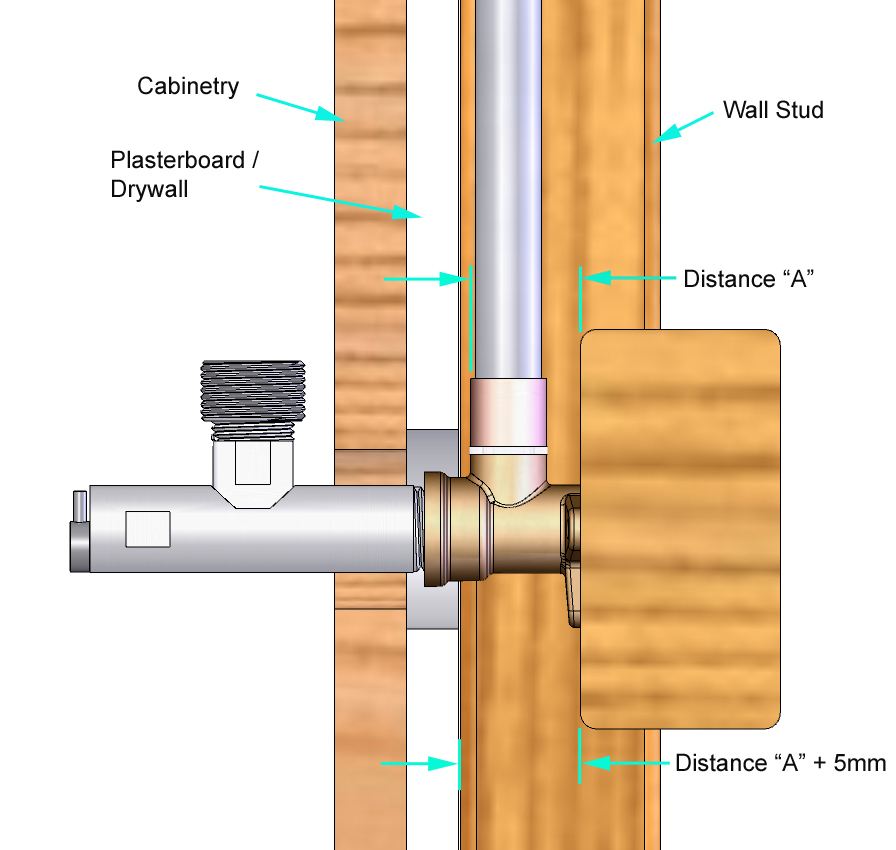

Installed in place of, and at the same time a traditional test plug would normally be installed, the Isovalve enables the wall board, tiles or joinery to be neatly drilled and installed over the Isovalve. Once the wall lining is completed it’s a simple matter of removing the protective cardboard sleeve from the Isovalve, sliding on the wall flange and attaching the fixture to the Isovalve outlet. The water is then turned on to the fixture at the Isovalve.

The Isovalve is manufactured from DZR chrome-finished solid brass rod, with only two components to the unit: the Valve Body and the Isonipple. It comes with a twin O-ring to the valve spindle and acetyl washer. It is controlled by turning the front dome, however a 4mm Allen key is also supplied with every Isovalve. It is suitable for all water pressures and will be supplied to the Australian market with a chrome finished cover plate. Each comes with its own in-line filter ensuring compliance with tapware warranties. There are presently four models of Isovalve available, including one dual outlet model.

The cost of installation depends on the number of fittings required but generally the Isovalve itself costs no more than a standard angle valve. The Isovalve will usually replace the test plug, brassbarrel nipple and sometimes an angle valve or a chrome or brass elbow. The real cost saving is in installation time and therefore labour costs. Future maintenance is also much easier where Isovalves have been installed.

Savings can also be made in water consumption.

In the bathroom, kitchen and laundry where maximum high pressure water flow is unnecessary, the water can be restricted at installation stage or at any time in the future.

To restrict or increase flow, simply turn the dome on the front of the Isovalve to meet individual needs. In public installations the Isovalve can be made tamper-proof once the required water flow has been set by simply removing the dome and replacing it with a chrome coloured plastic accessory plug. Isovalves work equally as well in both commercial and domestic situations. In a typical house with a 300L mains pressure water system, savings of around 40,000L of hot and cold water can be achieved. This equates to 65 hot water cylinders per year.

Business Development Manager for Isotec Ltd, Milton Weir believes that with the number of countries around the World now facing dire water shortage situations the Isovalve will become an important product in water conservation. He is now concentrating on countries other than NZ and Australia and is interested in hearing from potential distributors.

The Isovalve can be retrofitted or used in conjunction with older fittings; however, it is advised that a qualified tradesperson take care of installation.

The Isovalve is a simple idea that stemmed from a common problem. It provides an easier and cheaper way and saves time when fitting plumbing fixtures and dealing with water flow restriction. They say the simplest ideas are often the best.