Maintain the Drain

Drain cleaning is a dirty job but the introduction of new technologies in the marketplace has made inspecting and cleaning them a less arduous task. We look at five new products to consider before taking on your next drain cleaning operation.

The 21st century sewer inspection camera

The SparVision 200 is a drain inspection camera designed to make sewer inspection safer, easier and instant. At the end of a 200ft long high-efficiency push rod sits the SparVision 200’s self-levelling colour camera which takes instant snapshots, video, playback, audio dubbing and editing. All this can then be sent straight to your shop, or directly to the customer via the WiFi enabled unit.

The SparVision 200 uses either a Nexus 10 tablet or an Apple iPad as its touchscreen, allowing for simple and user friendly control, once you’ve downloaded the Spartan Tool SparVision 200 app. It has an onscreen keyboard, is waterproof and has a battery life that will last up to six hours on a single charge. The camera head lights can also be adjusted using the touchscreen controls.

With a wheelie design reminiscent to a small carry-on bag and weighing in at just over 15kg, the SparVision 200 is a light and mobile enough to be transported from workplace to workplace. While it’s heavy-duty rotationally modelled case protects the unit in harsh conditions, reducing potential damage.

As safety is paramount amongst all trades, the SparVision 200® offers you reliability, ease of use, no dangerous cords or open wounds of any kind.

To further assist you in discovering your problem is the optional Trap Eze, an ultra flexible camera which allows quick peeks into small drain lines, often without removing the trap. It connects to the SparVision 200, which automatically senses when the Trap Eze camera has been attached.

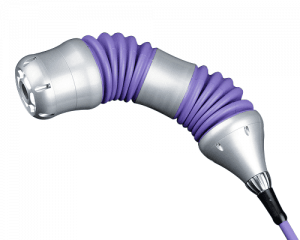

Flexible inspector

The camera CamFlex®, with turning capabilities, manufactured by Kummert enables users to reach branches with a diameter between DN100 and DN200 without problems. One special feature of this vermicular camera, which was developed specifically for the inspection of private sewerage systems, is its flexibility. This means that the camera can move from a straight position to a 90° angle, thus facilitating navigation into nearly all laterals and even through 90° bends.

One of the many positive qualities of the CamFlex® is the camera’s robustness.

On one hand, the concave shape accounts for minor wear of the outer shell due to the camera’s minute contact surface. On the other hand, the high-tech materials used give the camera additional protection. Aside from the outstanding durability, the CamFlex® offers an always upright image for an optimal orientation during the inspection. A perfect illumination, as well as a first-rate image quality facilitates high-quality TV inspections. The specialty of the camera CamFlex® is its ability to record the pipe run during an inspection in a three-dimensional manner. The internal sensors collect all necessary data needed for issuing a three-dimensional pipe plan in connection with the CamMobile® Profi 3.

Solving the greasy pipe problem

So you have been called out to your local Chinese restaurant that has suffered a blockage and the kitchen is starting to flood. On goes the jetter in a frantic rush to clear the blockage and finally the drain flows and the water from the floor rushes to the floor waste.

You know the drain was unblocked but not cleared and will block again, soon, and it will be all your fault. There has to be a better way and now there is – Grease Release

Grease Release is an industrial strength detergent with powerful penetrants that emulsifies fats, oils and grease (FOG) commonly found in sewer systems. Grease Release prevents FOG from re solidifying and this allows FOG to flow out of the effected drain and not cause another blockage downstream. Your sewer hose remains clean; allowing for hose handling without slippery grease contamination and that putrid smell.

Grease Release attaches to pipe surfaces to slow future FOG build up and will enhance preventative maintenance programs by coating surfaces with a grease repelling barrier. This makes your next cleaning of previously treated pipes easier, and more effective. Used regularly, it will help keep greasy sewer pipes flowing smoothly.

Grease Release is added to your jetting water at a 100:1 ratio and is pumped down the hose. It goes to work in combination with the thrusting power of the water jet to break up the grease. The pipe fills with a milky type texture and colour which is the broken down grease oil and fats. The pipe literally becomes squeaky clean and the residual surfactant slows the build up of future grease.

Grease Release is available in 1 and 5 litre jugs.

A whole repertoire

RIDGID® drain cleaning products have been delivering reliable performance to professional trades people for decades. Today, RIDGID offers a complete line of drain cleaning machines.

From hand tools, toilet augers and sink machines to drum, sectional, rodder and water jet machines, RIDGID has it covered.

The RIDGID drain cleaning legacy began with the sectional machine back in the 1930s while today, RIDGID offers a full line of sectional machines to clear everything from 2” up to 8” drain lines. Sectional machines like the K-1500B offer a unique instant-acting cable clutch that maximises operator control.

RIDGID drum machines like the K-750 clear lines from 3” to 8” and provide high torque to clear obstructions. This powerful machine is ideal for indoors as the drum keeps the cable and mess contained.

RIDGID sink machines are excellent for clearing blockages in small lines such as sinks, tubs and showers. They are lightweight, easy to use and feature a two-way AUTOFEED® system that makes it easy to get to those hard-to-reach areas such as under sink cabinets and bathtubs – advance and retrieve the cable with just the push of a lever. In addition, RIDGID SeeSnake® diagnostic and video camera inspection products allow professionals to capture digital video and still images inside drains to identify problem areas before they use a drain cleaning machine.

Rounding out the total solution is the RIDGID range of line location equipment which is used in conjunction with RIDGID camera systems and drain cleaners to locate pipes under the ground.

Rioned FLEXJET + trailer mounted jetter

The Flexjet + is a super compact trailer jetter with a powerful Speck 41 pump and 24 HP.Honda petrol engine which has the capacity of 140bar/60 litres/minute.

The hydraulic high pressure hose reel with 80m of 13mm (1/2”) hose is a professional jetter suitable for cleaning drains up to 400mm in diameter.

With a streamline design the Flexjet+ has low air resistance when towing and by utilising high strength steel and synthetic materials means the total weight is limited to 450kg with an empty tank.

Hose reels are mounted at the perfect height for ultimate operational comfort and a rear mounted control box gives the operator total control of the Flexjet+ where remote control operation is an option. For those worried about on road performance, the innovative construction of the 550 litre water tank gives stable road holding, whether empty or full.

Motor and pump compartment is noise dampened and the jetter can be operated with a closed compartment. Also of note is the tool box and water fill point being integral in tank moulding.

The new Flexjet+ was a sensation at the EFAT Show in Germany and is the latest European drain cleaning technology designed and manufactured by RIONED in the Netherlands.

SECA, which has been upplying the Plumbing and Drainage Industry for over 47 years, is proud to add the Flexjet+ to Australia’s largest range of draining cleaning, testing and inspection equipment.