EZiDIG buries the risk of down time

Now, an innovative new excavator-mounted system for locating and avoiding buried services, developed by Cable Detection, is available from Scanlaser in the UK. Importantly, the EZiDIG system, which is aimed at construction and utility contractors, is designed to detect buried services while the excavator is being used.

This can enable the amount of damage caused to buried services to be cut, decreases project downtime, enhances productivity and reduces the risk to excavator operators.

According to Scanlaser’s UK general manager, Simon Hogg, EZiDIG is a world first that takes location technology one step further into an area where no other products exist and is set to become a necessary addition to any excavator.

“With hand held locators, best practice requires repeated scans as the trench is dug, but human errors can result in damaged services and machinery as well as injured site workers. The EZiDIG system adds an additional, crucial level of safety to the excavation process because it continuously scans the area during excavation,” Hogg says.

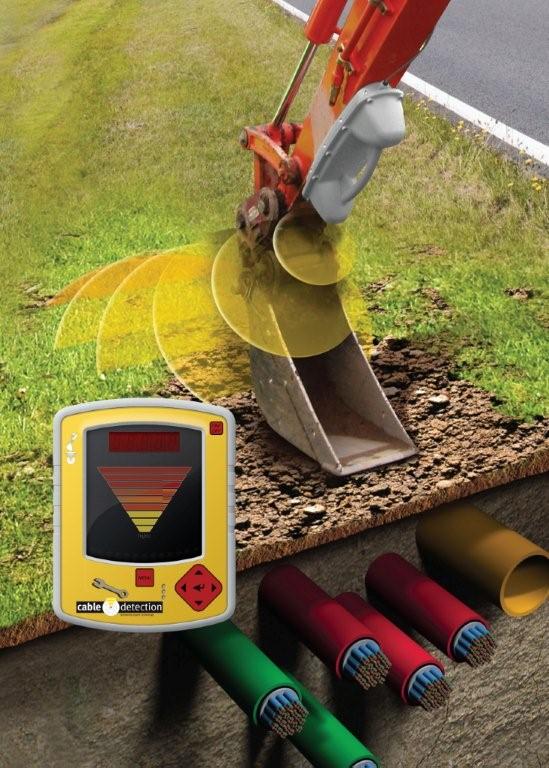

The EZiDIG system consists of a sensor unit and in-cab display screen, plus power box and connection cables. The sensor unit, which can be easily removed for security purposes, is attached to the excavator dipper arm by a high-strength magnet assembly connected to the power supply box.

If electromagnetic signals are detected from buried metallic services, real time communication is provided to the excavator operator via the in-cab display screen which gives both an audio warning and a visual graduated indication of the proximity of a buried service.

As Hogg points out, safety and productivity are both maximized because EZiDIG works with the operator rather than against the workflow by keeping him alert in real time to any threats.

“As the excavator arm moves over the area to be excavated the sensor picks up signals within its ‘pawprint’ up to two meters below the sensor. This system is designed to give a second-by-second warning of the presence of electromagnetic signals commonly carried on buried metallic services,” he says.

“The risk of project downtime can be significantly reduced, especially in an urban or developed environment. Not only are excavator operators no longer completely reliant on surveys prior to excavation, they are also not held up by on-the-job checks during excavation. Another plus is that companies can demonstrate a strong commitment to duty-of-care by installing EZiDIG and providing a greater level of safety for operators.

“Also, hydraulic hoses and cables are often damaged when excavators strike power cables and the maintenance and repair of equipment is a significant and increasing cost for owners. So EZiDIG provides another benefit by protecting assets and reducing repair costs. In addition, potential damage to the site and nearby buildings, threats to public safety and disruption to businesses, as well as the risk of litigation, can all be minimized.”

Scanlaser advises that the EZiDIG system, which costs approximately £3,500.00 fully fitted, is suitable for installation on excavators between two and ten ton. The system is available as a stand-alone solution or can be integrated into existing machine control systems either via an installed Mikrofyn MikroDigger XC2 system or customised to fit to a range of systems installed by excavator manufacturers or resellers.

EZiDIG recently won the Off-Highway Plant and Equipment Centre (OPERC) award for outstanding contribution to health and safety relating to buried services, as well as an award at the Aquatech Amsterdam 2008 Exhibition.