Extremist plumbing

A new name in the plumbing industry, Mitsubishi Heavy Industries Air Conditioners Australia has a long technical heritage in the air-conditioning market. Now, the company has introduced the new generation air to water heat pump to the Australian and New Zealand market. Adelle King reports.

Going ‘green’ isn’t just an emerging trend anymore, it’s becoming essential for manufacturers as consumers look for ways to reduce their carbon footprint and save money. As a result, a number of new technologies have entered the market aimed at helping plumbers and their customers become more eco-friendly.

One of these is ‘air to water’ heat pumps that can be used in a variety of applications for the supply of sanitary hot water.

Mitsubishi Heavy Industries Thermal Systems has developed a heat pump that uses this technology to transfer thermal energy from a place of low temperatures to another of high temperatures.

Mitsubishi Heavy Industries Thermal Systems is a 100% subsidiary of Mitsubishi Heavy Industries (MHI) and was formed in 2016 to provide innovative solutions for thermal issues around the world and contribute to the efficient energy usage and reduction of CO2 emissions.

“The compressor is the world’s first to employ a two-stage compression structure, a combination of rotary and scroll mechanisms that result in outstanding seasonal efficiency. This technology has now been incorporated into a commercial water heater and it operates the unit down to -25°C and without any capacity drop down to minus -7°C outdoor air temperature,” says Mitsubishi Heavy Industries Air-Conditioners Australia (MHIAA) A2W manager Trent Miller.

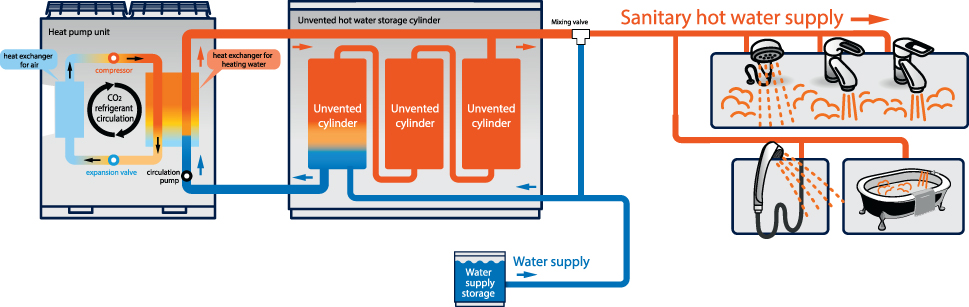

Known as Q-ton, the heat pump draws air through an evaporator that contains CO2 refrigerant, which absorbs the heat in the air. The two-stage compressor puts the refrigerant under high pressure in order to raise its temperature, while an on-board heat exchanger uses heat from the refrigerant to generate hot water, which is then stored in cylinders for sanitary use.

It provides an efficient solution to the old boiler and banks of gas instantaneous type systems found in most commercial settings and was developed in response to energy conservation requirements and concerns about global warming.

“CO2 as a refrigerant has a low global warming potential (GWP) of one, has been rated as having Ozone Depletion Potential (ODP) of zero, is non-flammable and is appropriate for high-temperature hot-water supply due to its refrigerant properties,” says Trent.

“As a result, CO2 has been widely used as a refrigerant for household heat-pump water heaters in Japan, and its use is also increasing in commercial and industrial fields.”

However, CO2 has a high operating pressure, leading to larger leakage and mechanical issues at the compressor so the reduction of these losses is essential to improve the performance of CO2 heat-pump water heaters.

“The improvements made by MHI Thermal Systems have made it possible to introduce heat-pump water heaters in cold regions,” says Trent.

Q-ton, which has WaterMark certification, runs like a boiler and can generate hot water from 60°C to 90°C, even in -25°C ambient temperatures, without requiring an electric immersion heater backup. It can therefore be used in a variety of applications, such as hotels, restaurants, apartment blocks, fitness centres, hospitals, universities, commercial laundries and aged care facilities.

“Efficiency improvements and higher reliability can be realised under a wide range of operating conditions with the Q-ton in comparison to conventional heat pump water heaters,” says Trent.

For example, to produce 90°C hot water at -7°C ambient temperature, Q-ton consumes 64% less energy than an electric water heater, according to MHI.

“The Q-ton works on the principle of storing water in stainless storage cylinders in varying configurations and then distributing this into the reticulation pipework. The design of Q-ton enables the production of hot water based around a 24-hour profile and can also be configured around off peak tariff or solar feed-in power periods,” says Trent.

“The remote monitoring capability and ability to collect large amounts of data allows accurate system profiling, resulting in the production of hot water at specific times and durations. This enables MHIAA to review the operation of the system and provide follow up information to the client for optimal profile setting and energy efficiency.

“The combination of the 24-hour profiling and the advanced inverter drive technology results in extremely efficient hot water production.”

There is no output reduction down to -7°C and Q-ton can be installed in a modular array of up to 16 units for a total of 480kW capacity. A 30kW Q-ton produces more than 600L per hour but the overall L/hr quantity of hot water production will vary depending on the feed water temperature, outdoor temperature condition and water outlet temperature set point.

To demonstrate the environmental and cost benefits, MHIAA has undertaken case studies of the Q-ton installation in two climatic extremes in Australia – Perisher Valley in NSW’s alpine region and Cairns in tropical northern Queensland.

At the Matterhorn Lodge Perisher, Q-ton is expected to help cut 50% of energy costs compared to a traditional boiler, while at the Harbour Lights Hotel in Cairns, Q-ton has saved the hotel considerable cost per annum by replacing liquid petroleum gas and instantaneous hot water heaters with five Q-tons and 9,000L of hot water storage capacity.

“These case studies show that Q-ton is the ideal solution for delivering hot water requirements for commercial facilities, providing flexibility and suitability across a range of applications,” says Trent.

“Customers also get more visibility about operation efficiency, which can help improve bottom lines.”

Mitsubishi Heavy Industries Air-Conditioners Australia

www.mhiaa.com.au

Mitsubishi Heavy Industries Thermal Systems

www.mhi-mth.co.jp/en

*This article was originally published in the summer 2018 edition of Plumbing Connection. Click here to subscribe.