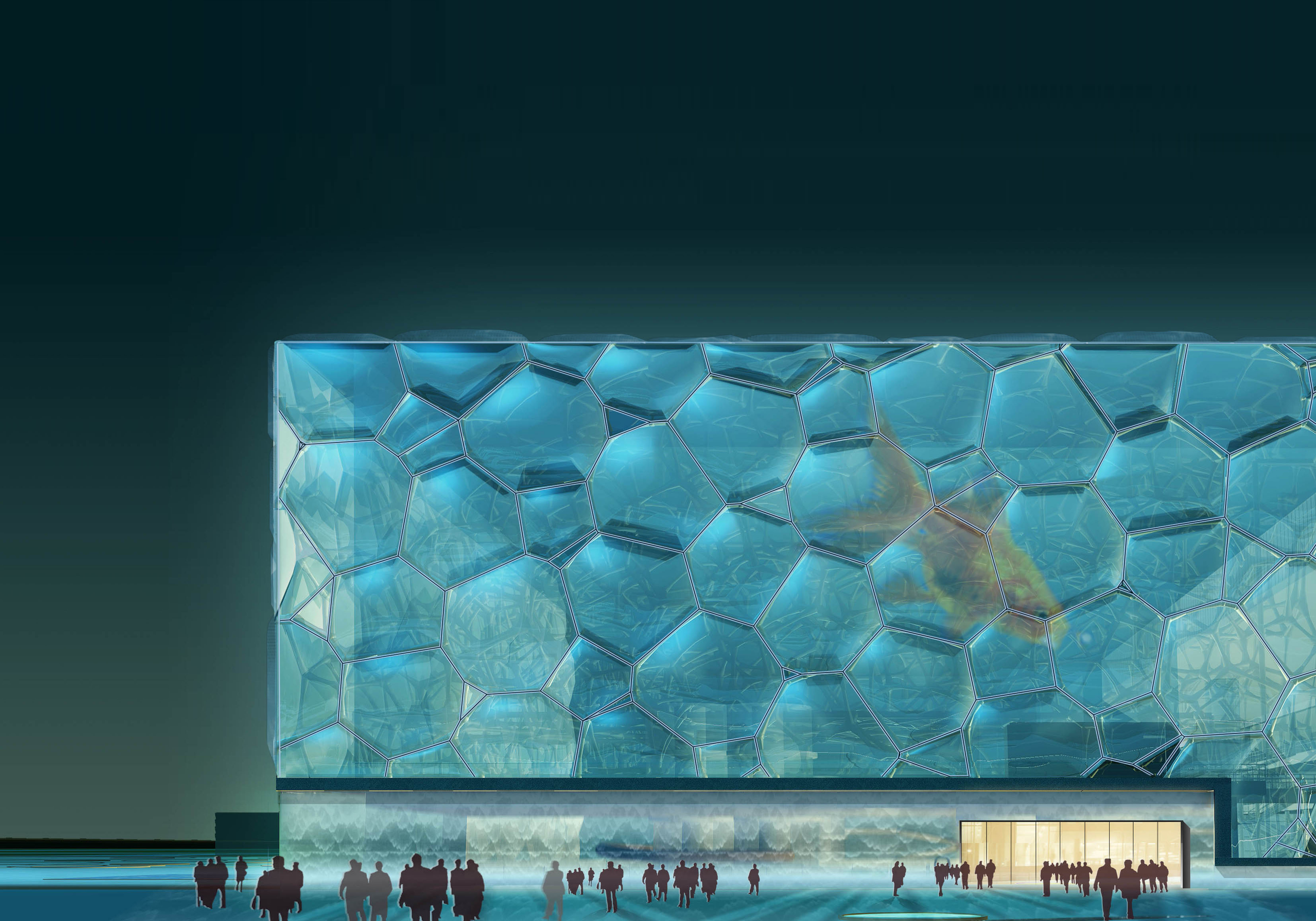

Constructing Beijing’s olympic pool

The ‘Water Cube’, which will house the Beijing National Swimming Centre at an estimated cost of $100 million, will be the height of a 10-storey building and be the largest Olympic swimming centre ever built.

With a gross floor area of 80,000m2, it will seat some 17,000 people and house two Olympic pools, a diving pool, leisure water features including water slides and a wave pool, together with related facilities.

This ambitious project was designed by a team of Australian engineers and architects together with two Chinese partner organisations, and the result is a fully integrated concept from both an engineering and architectural perspective.

Engineers from Arup and architects from PTW Architects in Sydney, in association with the China State Construction and Engineering Corporation (CSCEC) and the China Construction Design Institute (CCDI), came up with a concept based on the natural shape of water bubbles.

The engineers had the important role of clearly conveying to the architects what the building was required to achieve in terms of thermal, energy, hydraulic, environmental and technical performance.

Rapid prototyping was used to physically model the complex structure from CAD drawings and various CAD-driven scenarios were introduced to test the strength of the steel structure. Some 25,000 beam size variables and 57 million design constraints were analysed for strength.

PTW’s associate director, Mark Butler, who was the architect’s design leader for the project, says it was critical that the architects and engineers had a very close working relationship in developing the winning submission and then bringing the project to fruition.

“A total team effort was required. In the early stages of design, architects from our China partners worked with us in Sydney and as the project progressed our architects and Arup engineers joined the Chinese partners in Beijing,” Mr Butler says.

“At the concept stage we were looking for innovative ideas that would enable us to win the international competition. The design needed to be ‘Chinese’ in a modern way and to harmonise with the main stadium nearby.

“The design had to be about water and have a green theme. Cross-fertilisation of ideas was central to the team’s ability to break new engineering and architectural ground.

“The aims of the project and the engineering principles were clearly presented at the outset and then the pressure was on to achieve the agreed goals.

“During the design process it was particularly important to work closely with the engineers on the critical innovative parts of the building including the structure and facade, and many challenging issues had to be addressed such as creation of the bubbles and fire engineering.

“To ensure effective coordination, numerous 3D information models in multiple software formats were exchanged between the design partners throughout the entire design process.

“Once the team had successfully completed the initial scheme and won the competition, the project then progressed on to complete the design development and documentation.”

More than 80 Arup engineers and specialists spread across 12 disciplines and four countries were involved in various elements of the design.

The huge Water Cube complex is 177m wide, 177m (580ft) long and 31m (101ft) high, and the structure is made from a network of steel tubular members clad with translucent ETFE (Ethyl Tetra Fluoro Ethylene) pillows.

A strain of fluoro polymer, ETFE is a strong recyclable lightweight material that lets in more light than glass but is resistant to the weathering effects of sunlight.

The skin of the swimming centre, which covers both the inside and outside of the structure, has 100,000m2 (1,076,000ft2) of ETFE bubble cladding that contains around 4,000 bubbles of various size.

The complicated support structure of the Water Cube consists of 22,000 steel tubes welded to 12,000 steel nodes which vary in size according to the loads placed upon them. If laid end-to-end the steel beams would stretch for 90 kilometres (56 miles).

A key design factor was the need to minimise the weight of the steel structure because in long roof spans self-weight is critical as the roof spends a lot of its strength simply holding itself up.

Although lightweight, the Water Cube structure is very strong and conforms to the new Chinese steel/seismic design Codes.

To maintain the aesthetic appeal of the Water Cube design, roof penetrations are kept to a minimum through the extensive use of air-admittance valves in the sanitary plumbing.

Because the Water Cube did not fit with China’s prescriptive building Code it was necessary to demonstrate that the design provided for an acceptable level of safety.

A smart building

The solution was to use performance-based fire engineering to develop a set of provisions specifically tailored to that building, including sprinkler and smoke exhaust systems.

This enabled the team to design away from the Chinese Code while being supported by research and international guidelines.

The team was also able to demonstrate that the ETFE facade material would shrink away from a fire and thus let smoke out of the building by self-venting.

A key requirement for the building is environmental sustainability, including a very high energy-efficiency rating and the ability to recycle at least 80% of its water.

The Water Cube is designed to act as a greenhouse to help deal with Beijing’s extreme climate which can swing from -13°C (8.6°F) in winter to 36°C (96.8°F) in summer.

The transparent ETFE cladding saves energy costs by allowing a lot of natural light into the building, and some 90% of the ambient solar energy will be trapped and used to heat the pools and interior area.

Cladding heat loads are minimised in summer but maximized in winter by ventilating the heat out of the wall cavity in summer and containing it in winter.

Swimming pools can create condensation and corrosion issues, so effective air distribution is important. This will be addressed by locating nozzles around the perimeter of the building to supply air up the walls.

In this smart building the air conditioning system is targeted to prevent wastage to areas which are not used by people. For example, the area where spectators sit will be air conditioned separately by an under-seating supply system that will only be activated during events.

Heat rejection from the air conditioning can also be used to heat the pools.Other energy-saving systems include heat recovery from chillers and from ice making machines which is used for space and pool water heating.

Smart hydraulics

Key hydraulic design and plumbing features of the Water Cube include siphonic drainage for storm water, water-efficient fittings, collection of storm water for domestic hot water supply, and greywater recycling.

Ken Ma, a senior associate at Arup in Sydney, says water in northern China is a valuable commodity and Beijing currently lacks a reliable water resource to meet existing and projected demand requirements.

“Swimming centres consume a large amount of water for sanitary purposes and in relation to the pool filtration system backwash. Therefore, central to the design philosophy that underpins the Water Cube is the core objective of water conservation,” Mr Ma says.

“More specifically, this means the design of water-efficient systems that minimise water consumption and maximise reuse and recycling opportunities.

“The aim is to reduce the reliance on the municipal water supply system and discharging to the municipal sewer system, which in turn will reduce the pressure on local receiving waters.

“The rain collected in box gutters and sumps on the roof is drained to an energy dissipation pit via a siphonic system. This water is then drained by gravity to a silt arrestor and screened first flush pit prior to connection to underground storage.

“The storage is sealed with a liner and filled with coarse sand and ‘zeolite’ as a filtration medium. Filtered water is then pumped for further treatment which includes aeration, fine filtration, ultraviolet disinfection and chlorination. It is then reticulated to showers and basins as a non-potable hot water supply to amenities and ablutions only.

“During the colder months pipe freezing can be an issue in Beijing and this has been addressed by including an electric heat trace on external rainwater outlets and downpipes.

“Greywater from wash basins and showers will be drained to a central underground storage tank before being pumped to the greywater treatment plant incorporating the following:

• Stage 1 – 2mm (0.07in) course filtration unit

• Stage 2 – biological treatment unit with integral sludge digestion

• Stage 3 – micro-filtration unit and aeration

• Stage 4 – high capacity uv disinfection unit

• Stage 5 – pH correction unit

• Stage 6 – chlorine residual dosing unit.

“All filtration devices will have automatic backwash that pumps sludge to the sewer. The treated greywater may then be used for toilet and urinal flushing, wash-down, water features and irrigation.

“Blackwater from toilets is gravity fed directly into the municipal sewer system.”

The Beijing Water Cube is a great example of international cooperation between architects and engineers of many disciplines, for the construction of an outstanding landmark that is sure to endure long after the XXIX Olympiad has passed.