Consider using water-source heat pumps

As hydraulic engineers consider ways to improve overall building efficiency, one product that could be considered more frequently is a water-source heat pump (WSHP) for domestic hot water applications. Hydraulic engineer Konrad Perry from Aurecon comments.

Unlike air-source heat pumps, WSHPs use a ‘water source’ from a nearby mechanical system such as chilled water or condenser loop water. WSHPs can also be used as ground-source heat pumps; however, this article will focus on mechanical water sources. By taking heat energy from the mechanical system and transferring it to the domestic hot water system, the overall coefficient of performance (COP) can double! There are important considerations when using such a system, though, and this article will aim to highlight these.

Dual functionality

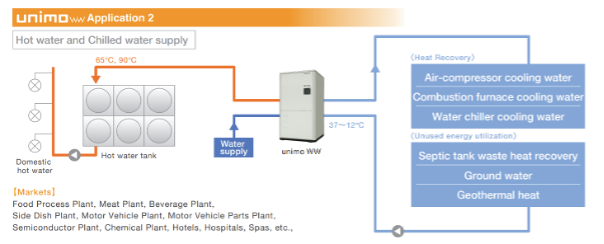

One of the main benefits of WSHPs is their dual functionality. These systems can integrate with chilled water or condenser loop return water from mechanical systems to heat domestic hot water. This dual effect – simultaneously cooling and heating – can enhance overall system efficiency. Acting as both a chiller and heater in a single unit, WSHPs extract energy from the mechanical loop, cooling the return water while heating domestic hot water (See Figure 1). As a result, they can achieve a COP of 6–8 during peak operation.

Anecdotally, I have heard that WSHPs account for only 1% of the domestic hot water heat pump sales in Australia. In my view, there is a compelling case for wider use of these units in applications like residential towers, office buildings, and other structures that require both domestic hot water and chillers or low-temperature heat pumps. This is especially true in buildings with high cooling demand, such as during summer periods or warmer climates.

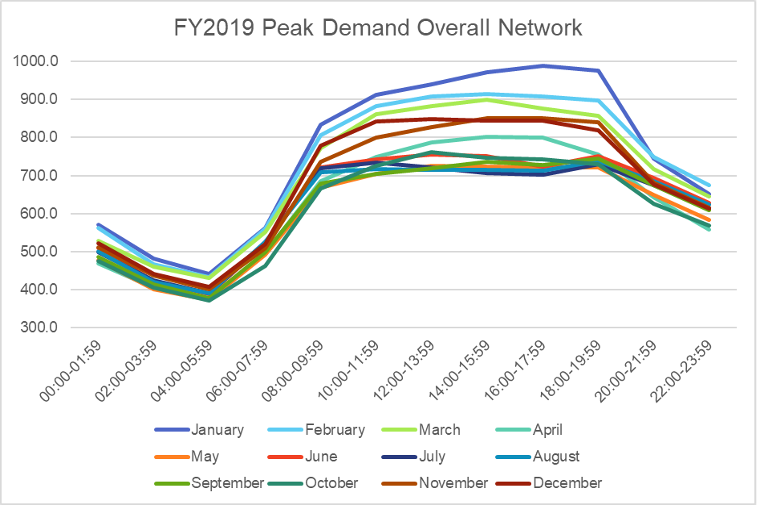

In residential towers that use a condenser loop instead of split-system air conditioning for each apartment, WSHPs can significantly enhance the overall energy efficiency of the building’s plant equipment, particularly during summer when cooling demand is highest. Research by Aurecon has found that electrical demand in the City of Sydney council area can be nearly 50% higher in summer compared to winter (see Figure 2). Connecting WSHPs to the condenser loop allows the domestic hot water plant to extract heat energy from the mechanical loop, reducing both energy consumption and electrical strain on the infrastructure. However, careful consideration must be given to the temperature variations in the condenser loop throughout the year, which can range from 15°C in winter to 37°C in summer. Therefore, WSHPs should be selected to operate effectively across this temperature range.

Temperature agnostic

Another benefit is that WSHP performance is unaffected by ambient temperature, unlike air-source heat pumps. Instead, it depends on the temperature and flow rate of the incoming water source. It is important to carefully assess the water source and size the DHW system based on the lowest anticipated water temperatures, similar to sizing air-source heat pumps for a cold winter’s morning. Mechanical systems, which are typically much larger than domestic hot water systems, can provide stable supply temperatures throughout a 24-hour period. This stability contrasts with fluctuating ambient temperatures, which can significantly impact air-source heat pump capacity – particularly during early morning peaks when demand is high, but ambient temperatures are at their lowest. However, further thought is required for certain scenarios, which will be highlighted further in this article.

Space benefits

WSHPs offer significant space and form factor benefits. Their reduced ventilation needs allow them to be installed in internal plant rooms with minimal mechanical ventilation, eliminating the need for large louvres. Service access is typically only required at the front and rear, enabling side-by-side installation. Additionally, ventilation clearances are not needed due to the low air flow requirements, making them ideal for space-constrained projects like residential tower plant rooms.

Selection criteria

If selecting a WHSP, several key considerations must be addressed. Firstly, a suitable water source is essential; if there is no mechanical condenser or chilled water loop, an alternative system must be implemented.

The consistency and temperature of the water source require careful coordination between the mechanical and hydraulic engineers. This includes managing the interface and controls between the mechanical and hydraulic systems. Adequate water flow is crucial to ensure efficient heat extraction without overcooling the source. For example, in an end-of-trip facility with numerous showers in an office or university building, challenges may arise if the domestic hot water plant is connected to the chilled water loop. Recovery of hot water could become difficult on cold winter mornings when there is minimal cooling demand from the mechanical system. The minimum cooling demand should be calculated and compared to the required energy for the WSHP to ensure compatibility and no issues will arise.

Clear and detailed design documentation is critical. It must be effectively communicated to the builder and subcontractors, with clear delineation of responsibilities. Issues can arise if the mechanical component is omitted from design drawings, leading to complications during or after the tender phase.

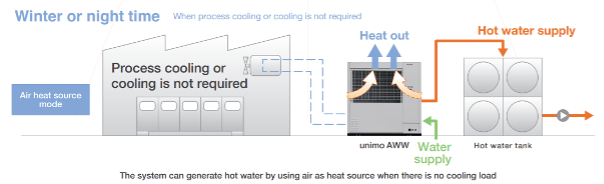

There is also hesitancy among hydraulic engineers and designers to adopt WSHPs due to their complexity and reliance on mechanical systems. Concerns such as potential mechanical system failure and redundancy must be addressed. These risks can be mitigated, however, with solutions such as electric element storage tanks that activate as a backup during mechanical system failures. Additionally, some heat pumps, like the Mayekawa Unimo AWW, as supplied by Hunt Heating, offer dual functionality, allowing them to alternate from water source to air source function if the mechanical system fails (See Figure 3). An interesting technology that can provide the necessary DHW plant redundancy.

Upfront costs

Finally, installing WSHPs typically involves higher upfront costs compared to air-source heat pumps, driven by the expense of advanced controls and additional costs from integration with condenser or chilled water loops. However, WSHPs can offer significant long-term savings through lower energy consumption, reduced operational costs, and enhanced system efficiency, making them a cost-effective and sustainable solution over time. Any comparisons should be calculated against the particular scenario being designed to.

WSHPs offer an efficient and versatile solution for heating domestic hot water while enhancing overall building energy performance. By utilising stable water temperatures from mechanical systems, such as condenser or chilled water loops, they excel in applications with high cooling demands, providing simultaneous heating and cooling to improve system efficiency and reduce costs. However, successful implementation requires careful planning, including water source stability, system sizing, integration, and redundancy measures. As a sustainable and energy-efficient technology, WSHPs align with modern environmental goals, offering long-term benefits when thoughtfully designed and executed.