Why correct thread profiles now matter more under AS 3688:2016

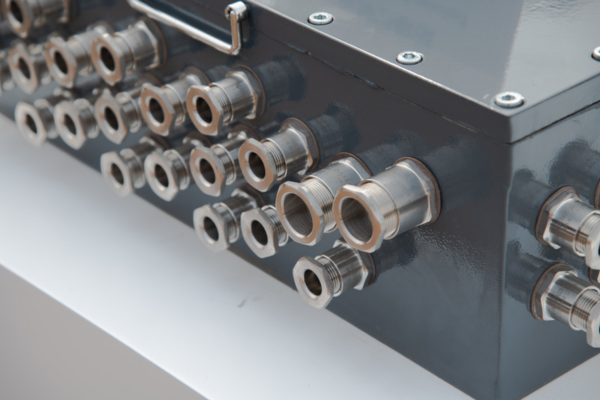

Metallic fittings and end connectors used in water supply and gas systems have been under review in AS 3688 to tighten the thread profiles, Terry Nguyen explains.

There are more than 100 Australian Standards and Technical Specifications detailing minimum design characteristics and performance requirements under WaterMark. AS 3688 was updated and re-issued as the 2016 edition last year, and with recent changes mandated by the Australian Building Codes Board (ABCB) superseding the previous version, manufacturers have begun looking into the new Standard to ensure that their products still meet compliance.

AS 3688 is the Australian Standard which outlines the design characteristics for plumbing connection ends to ensure plumbers are able to mate fittings or components together using known jointing techniques. It plays an important role in ensuring plumbers are not presented with unusual or incorrect thread types in the field, where a seven year warranty on workmanship must still be applied. A quick gap assessment between the latest edition to the previous edition (AS 3688:2005 +A1) not only reveals inclusions to the scope but also additional design criteria which previously was a little less clear.

Plumbing threads have had a distinctive change to the format and content under the relevant section in the Standard where at first glance it appears as though additional requirements have been imposed. The reality is that the thread design is essentially the same, but the manner in which they are assessed has been refined.

The superseded 2005 edition of AS 3688 referenced the same thread forms but critical parameters of a thread were not defined, meaning it was possible for a fitting or valve to be manufactured with threaded end connectors with an incorrect thread profile at the point of installation. These missing parameters made slightly incorrect thread forms difficult for some manufacturers to detect, difficult for some test laboratories and certification bodies to interpret, and ultimately difficult for any level of consistency of threads to be achieved within WaterMark.

The majority of the differences are found in sealing thread design. Sealing threads are those in which a watertight seal is designed to be effected on the thread itself, usually through PTFE tape or a liquid thread sealant. Sealing threads must be manufactured correctly so that the tapered male thread is wedged into the mating female where the selected sealing compound is squashed together to hold mains water pressure.

Incorrect mating threads may require more than a recommended amount of PTFE tape to bring the two components together before the male thread bottoms out prior to a proper seal being made. The other extreme could see only a couple of threads being engaged to maintain a seal beyond a plumber’s warranty period and for the designed lifetime of the plumbing system. When the mating threads barely engage, the likelihood of a leak is unnecessarily increased.

AS 3688:2016 has provided definition of the critical design parameters for sealing threads meaning that an incorrectly manufactured thread is far more likely to be detected at the type test stage prior to the product entering the market. In the diagram ‘Male Sealing Threads’ shows a sectioned view of a tapered male sealing thread. Dimensions B and C are new to AS 3688:2016 but not new to the design of an R series BSP thread. These dimensions only existed before as indirect design criteria for manufacturing. The latest edition of the Standard has these parameters noted to ensure that they are not inadvertently missed during testing and certification.

Dimension B is known as the gauge length, and is the theoretical location at which the tapered male thread will bind with the mating female thread. Having this known location is crucial to the end connection so that the contact point is established, allowing the manufacturer to make suitable allowances either side for the threads to come together without interference. Dimension C is referred to as the minimum fitting allowance which is provided knowing that the mating threads will encounter a substantial wrenching torque where the male is threaded in well past the theoretical gauge plane where the threads initially meet.

In simple terms this means that the threads meet initially at the known location B and there is an adequate distance C beyond this contact point where the plumber is able to wrench the components together as needed.

The mating female threads are also given the appropriate definition for critical dimensions to ensure a male thread is able to create an effective watertight seal. Diagram ‘Female Sealing Threads’ shows a sectioned view of female sealing threads where critical dimensions B and E are shown. Again, these are new to AS 3688:2016 but not to the basic thread design of Rp threads where these should have been met when complying with the superseded Standard. Dimension B ensures that the female threaded component has enough accommodation length to accept a correctly formed male tapered sealing thread. Dimension E is provided as the minimum amount of thread that is needed to create an adequate seal and withstand torque loadings expected during installation if the fitting has enough free run out behind the thread where the accommodation length is still maintained.

In simple terms this means that the female thread has enough free length for a male thread to create a seal at the correct location before interference is encountered preventing further engagement.

The new definitions under AS 3688:2016 will ensure that both new and existing fittings are tested and assessed appropriately to provide a greater surety that robust connections can be made by Australian plumbers. Most plumbers will already know a good connection by feel when threading mating components together and the Standard revisions should come as a welcome inclusion. Whilst the industry adapts to continual compliance, our licensed practitioners can rest assured knowing that leading manufacturers have already designed and allowed for the now reportable and tested parameters under the new AS 3688:2016 Standard.