Geothermal Is a Gift to Us All

If you’re looking for a way to expand your knowledge and get into a fast-growing renewable energy sector, then geothermal might be the answer, writes heat pump industry expert RICHARD JEFFORD…

A low-temperature geothermal system takes energy from the ground and transfers it into the house, saving thousands of dollars a year on run costs. It’s why geothermal or ground-source heat pump technology is the most efficient technology currently available for Australian homes. But it does come at a higher capital cost.

More consumers are choosing geothermal technology to heat and cool their homes because it runs off electricity. The benefits of this technology are even greater when combined with a solar system, providing consumers with more leverage and control over their utility costs.

WHAT IS A GEOTHERMAL HEAT PUMP? WHY IS IT USED?

What is a geothermal heat pump and why is it used?

A geothermal or water-to-water heat pump uses a refrigerant, the same as a refrigerator, to take energy from one place and transfer it to another with a low electrical energy input. Geothermal systems last for a very long time, with the average life cycle of a GSHP (ground-source heat pump) generally double that of conventional equipment. The ground loop lasts even longer, with an estimated life cycle of 50+ 50+ 50+ years. The loop life is measured this way because the plastics being used have only been around for 60-odd years (in the US they carry a 50-year warranty).

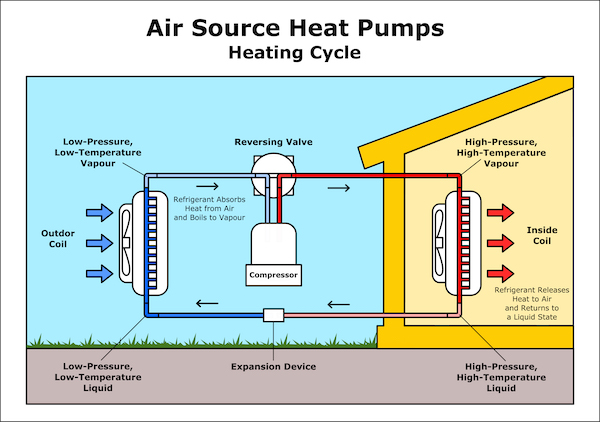

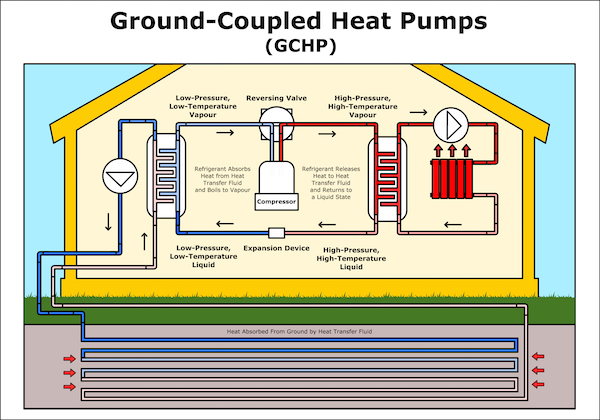

The heat pump works by a means of phase changing; from a liquid refrigerant over a heat exchanger (low pressure – low temperature side) which then absorbs the heat and converts it to a gas. This gas is then passed through a compressor and/or a reversing valve and then over another heat exchanger (high pressure – high temperature side) that extracts the heat and distributes it.

An air source heat pump (see Image 1 below) uses direct exchange (DX) like your typical split air conditioning system. The refrigerant runs in the one cycle from air outside to air inside. In the plumbing industry we like to use water as the best means of transferring energy, as it is future-proofed and environmentally friendly. Water can hold 3,000 times more energy than the same air volume. There is a big worldwide push for using better, less harmful refrigerants and the Australian Government this year has imposed a maximum GWP (Global warming potential) of 750 GWP for all new and imported residential split heating and cooling air conditioning systems.

Image 1: Air-source heat pumps are now well known internationally.

In a ground-source heat pump (see Image 2 below) the technology is very similar, except it uses water as a transfer medium from one source to the refrigerant, and delivers the same to the end use via water. The delivery method can be floor hydronics, wall panel radiators, forced air ducted heating or cooling, domestic hot water, and/or pool heating.

Image 2: Ground-coupled heat pumps are resilient, have incredible lifespans, and are well suited to diverse climatic conditions.

KEY ADVANTAGES

The key advantages of a ground-source heat pump over air are the constant, stable temperatures in the ground. Where I live in the Southern Highlands of NSW at 600+ metres above sea level, we see ambient temperatures down as low as -5°C in winter. The ground temperature where the pipes are placed for geothermal can be between 15°C and 19°C year-round. At this temperature, the heat pumps run at 300% to 500% efficiency, meaning from one kilowatt of electricity we get between 3 and 5 kilowatts of usable energy out. This is usually referred to as the coefficient of performance or COP. An air-source (air conditioning) system using the air temperature can be less than half this efficiency annually (about 2 COP compared to 3–5 COP).

Image 3: Horizontal pipework like this is often referred to a six-pipe racetrack. (Site photo courtesy HGX installations.)

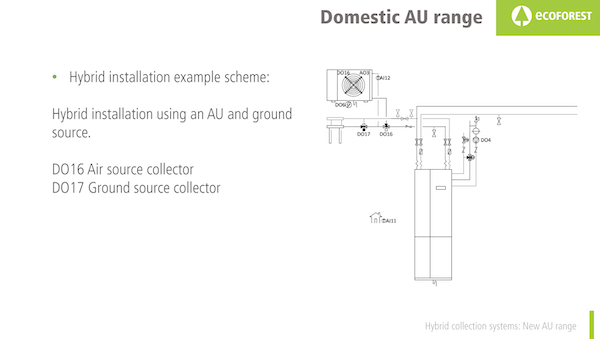

A ground-source heat pump can be used in almost any application and any location in Australia. The connection to ground comes in many forms: horizontal type (used in areas with available land, see Image 3 above); vertical (drilling boreholes and inserting a pipe with a u-bend for the water reticulation, see Image 4 below); pond/water loops (suspending pipes in a body of water); and/or open loops. Some manufacturers can also add in multiple sources connected to the heat pump, like an added dry cooler (see Image 5 below). When we use this hybrid form of ground loop the heat pump can select between higher air or ground temperatures, whichever is the most efficient at that time, giving an even higher efficiency.

Image 4: A vertical pipe system is ideal for applications where the land area is small, or where machinery access is limited. (Site photo courtesy HGX installations.)

Water-to-water heat pumps can also operate solely off a dry cooler (air) or the ground, or combinations of either. There are some international cases that are using warm sewer wastewater temperature to run a heat pump. The sewer has an average temperature of 21˚C, greatly increasing efficiency and reducing the energy demand.

Image 5: A hybrid system can allow the unit to switch between energy sources depending on seasonal conditions, for example. (Dry cooler hybrid configuration courtesy Ecoforest.)

STRAIGHTFORWARD INSTALLATION

Ground-source heat pumps can be easily installed using conventional methods that plumbers are familiar with. The ground loop, as shown in Image 3 with a six-pipe horizontal layout, involves digging a trench and laying poly pipes. There are different pipe configurations that can be used for a horizontal system. There are not many places in Australia where geothermal can’t be installed – usually only when the rock or soil type won’t transfer temperature in the ground. Low-temperature geothermal can be used in single dwelling homes, townhouses, apartments, and/or housing developments. Some of the best opportunities are in greenfield sites, creating a ‘district’ geothermal system to every home.

The work usually starts after a heat load design has been produced to determine how many killowatts are needed to heat and cool the house/system. Then a trench/loop design and size is worked out for the ground loop system (some manufacturers have a guide or rule of thumb calculation for this). As Australia is such a large, varied country with climate extremes, geothermal has excellent value opportunties in both hot or cold areas, as the ground will be a more stable medium.

At Highlands GeoExchange, for instance, we use engineers qualified in geothermal design to work out the house load and the ground loop design and length. This will ensure the system has the capacity to work as efficiently as possible and will last the anticipated life.

ONLINE TRAINING

Plumbers thinking about getting into the industry can undertake online training through the International Ground Source Heat Pump Association at https://igshpa.org/. The course outlines how to calculate what you need based on pipe design, soil type, and all the fundamentals of pressure drops and piping systems that most plumbers have studied. There are specific drilling companies that can do a design and the drilling for your project, but this may not be the most economical way to get the ground loops installed. However, it may be a path to ease your way into geothermal system installation.

Endnote

Richard Jefford from Highlands GeoExchange & Ecotherm Australia is a licensed mechanical plumber and has worked in the geothermal industry since 2012. His passion is to make geothermal more accessible to everyone in Australia through industry education. He is trained in geothermal pipe design, equipment service/installation, commercial geothermal design, and is an IGSHPA member.

Email Richard at info@highlandsgeoexchange.com.au

This article first appeared in the Summer 2024 issue of Plumbing Connection.